RFID: Key technology for the Smart Factory

Optimum traceability in your supply chain: RFID technology (radio frequency identification) plays a crucial role for production companies on the way to the smart factory. It ensures improved efficiency and accuracy in the labelling and traceability of products. And is a fundamental step for your comprehensively networked and intelligent production environment.

What RFID means for your production

Automated processes & centralised data

RFID systems use radio waves to identify and localise objects. This technology enables your production company to reach a new level of automation.

Real-time asset tracking:

With RFID, you can monitor your products and resources in real time. This enables precise control and optimisation of your production processes.

Automated inventory management:

RFID facilitates the automatic recording of your stock levels even without direct visual contact, reducing manual errors and saving you valuable time.

Improved process efficiency:

Data is recorded quickly and accurately using RFID. This maximises the efficiency of your production planning and control.

Increased security and quality assurance:

The seamless traceability of your products enables you to ensure optimum quality management.

Support for Lean Management:

RFID helps you to implement Lean Management principles because it minimises waste and maximises process efficiency.

For complete

traceability of all units

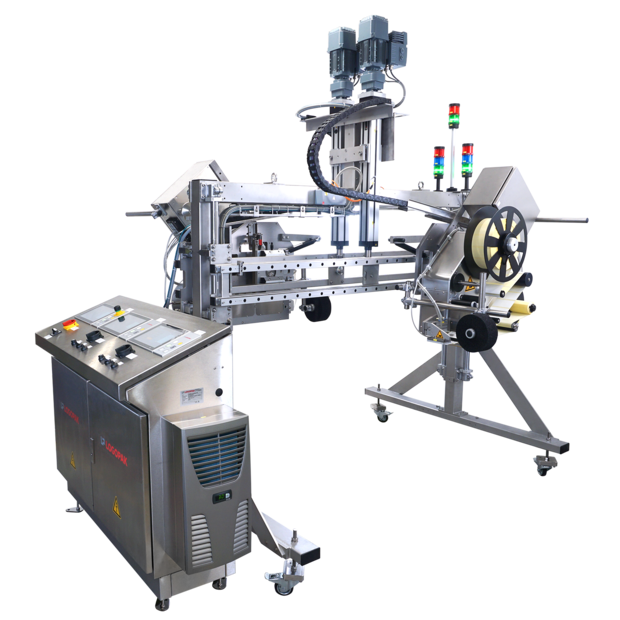

RAIN RFID labelling systems and labels from LogopakWould you like to utilise the benefits of RFID technology for your company? Use our RFID labelling systems for the secure programming and application of smart RFID labels. With our solutions, you can automatically identify and localise workpieces, tools, products and transport carriers along the entire value chain at any time – from the initial raw material to the sale of the finished product to your customers. Complete traceability for your supply chain.

Seamless traceability and monitoring

Monitor the entire life cycle of your products – from production to delivery. With our RFID labels, you receive automated real-time data for a perfect overview of your stock levels and production processes.

Optimised quality management

Continuous monitoring of products reduces errors and rejects. You save costs and increase customer satisfaction at the same time, because more accurate and faster deliveries allow you to offer your customers a better service.

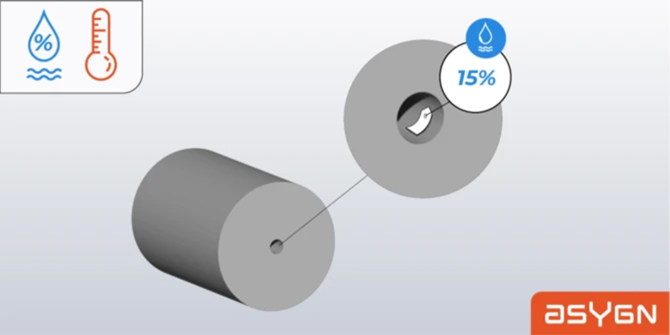

Proactive Humidity Monitoring

Detect and respond to moisture fluctuations before they cause damage. Our RFID humidity sensors provide real-time data, enabling proactive decisions to protect sensitive materials. Seamless integration into existing RFID systems helps optimise storage conditions and reduce the risk of mould formation and product losses.

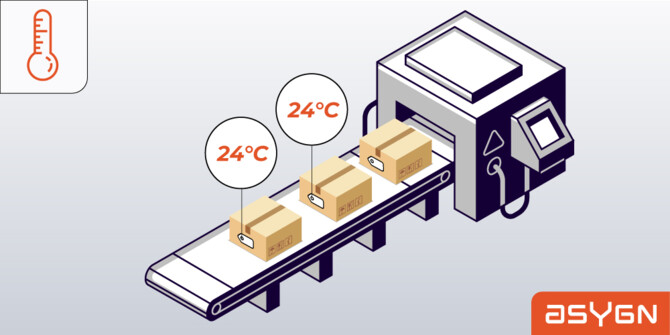

Intelligent Temperature Control

Enhance temperature-sensitive supply chains with real-time RFID monitoring. Our battery-free temperature sensors continuously track environmental conditions, helping ensure product integrity and compliance. By integrating seamlessly into Logopak’s labelling processes, they support efficient cold chain logistics and quality assurance.

Our RFID labels – your benefits

Maximum transparencyAutomated data recording:

Thanks to our RFID labels, your data is captured automatically and accurately. This allows you to optimally track your products, even in complex production processes. And you save yourself the trouble of errors that occur when entering data manually.

Complete traceability:

With our RFID labels, you can track every step of your product in the manufacturing process. This is particularly important for quality control, traceability and compliance.

Increased efficiency in production:

Our RFID labels can speed up your production processes by reducing manual scanning and enabling seamless integration of your manufacturing processes.

Real-time tracking and visibility:

With our RFID labels, you can monitor your products and materials in real time. This gives you better control over the entire production and delivery process.

Flexibility in labelling:

Our RFID labels can be applied to numerous materials and are available in various shapes and sizes. Suitable for a wide range of applications in industrial labelling.

Improved quality assurance:

Our RFID labels help monitor and track your products, simplifying quality assurance and compliance with standards.

Increased security and authentication:

Our RFID labels can be used to secure products against counterfeiting and theft by facilitating authentication and security checks.

News from Logopak

FAQ

What is RAIN RFID and how does it work?

- RFID stands for Radio Frequency Identification. It is a technology that uses radio waves to transmit data from an RFID tag to a reader. These tags can be attached to products or other objects and enable them to be identified and tracked in real time.

How does the RAIN standards promote the use of RFID?

- Through support of RAIN RFID, the actual use is covered by GS1 and ISO standards. These are international and support global supply chains for example.

How can RFID be used in industrial manufacturing?

- In industrial manufacturing, RFID is used to automate inventory management, to trace products through the manufacturing process, for quality assurance and to increase efficiency. It enables precise control and analysis of production processes.

What are the benefits of RFID for manufacturing companies?

- RFID offers numerous benefits, including improved efficiency and accuracy in inventory management, increased process speed, reduced labour costs, improved data quality and the ability to monitor and control processes in real time.

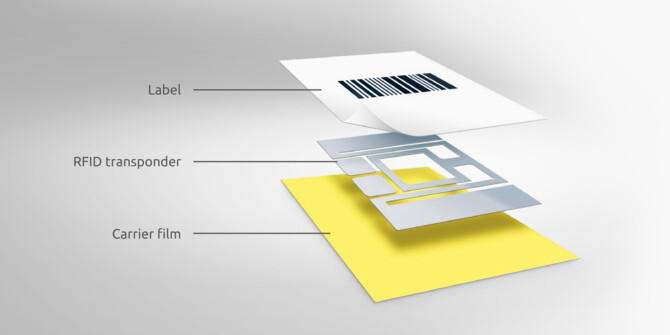

What are RFID labels and how do they work?

- RFID labels, also known as RFID tags, are small devices that contain an RFID chip and an antenna. They communicate with an RFID reader using radio waves to transmit data such as identification numbers or other specific information.

In which industries are RFID labels typically used?

- RFID labels are widely used in various industries, including logistics, retail, manufacturing, healthcare and other areas where accurate tracking of products or equipment is required.

What information can be stored on an RFID label?

- The information stored can range from simple identification numbers to detailed data about the product, such as date of manufacture, origin, destination and other specific attributes.

How do RFID labels differ from conventional barcodes?

- Unlike barcodes, RFID labels do not require direct visual contact to read the data and can simultaneously read multiple labels from a distance. They also offer greater storage capacity and are more resistant to environmental influences.

Can RFID labels be used in harsh production environments?

- Yes, there are specially developed RFID tags that are designed for use in harsh environments, including those that are resistant to moisture, dirt, chemicals and extreme temperatures.

How do RFID labels influence production efficiency?

- RFID labels make a significant contribution to increasing production efficiency by enabling fast and accurate data capture, supporting process automation and enabling better monitoring and control of production processes.

Are RFID labels cost effective?

- Although the initial cost may be higher than traditional labelling methods, the long-term efficiency gains and reduction in errors and waste often lead to a quick return on investment.

Can Logopak’s RFID solutions be integrated into existing systems in a smart factory?

- Yes, Logopak’s RFID systems are flexible and can be easily integrated into existing IT infrastructures and production management systems.

How secure are RFID systems from Logopak?

- RFID systems from Logopak are secure and reliable. They can be equipped with encryption and security protocols to prevent data misuse and unauthorised access.

Does RFID also support sustainability goals in production?

- Yes, by optimising production processes and reducing waste, RFID contributes to sustainability in production by using resources more efficiently and minimising waste.