Hartenholm, August 2025 – Logopak Systeme will be presenting new labelling solutions for the beverage and liquid food industry at drinktec 2025 in Munich (15–19 September, Hall C2, Stand 448). The focus is on technologies that reduce energy consumption and waste, digitalise processes and help companies implement the requirements of the future EU Packaging and Packaging Waste Regulation (PPWR).

With over 1,000 exhibitors from 55 countries, the drinktec trade fair sees itself as a global economic summit and a technological driving force for the beverage and liquid food industry – and thus as a global platform for innovation, networking and the future of the industry. "With its portfolio of high-performance, sustainable and digitalised labelling solutions, Logopak makes important contributions to key trade fair topics such as circularity and resource management or Data2Value – in other words, to efficient and resource-saving circular economy in beverage production and data-based value creation," explains Steffan Gold, Managing Director at Logopak Systeme. "That's why we're in exactly the right place here with our labelling solutions for breweries, mineral water producers, beverage and liquid food manufacturers."

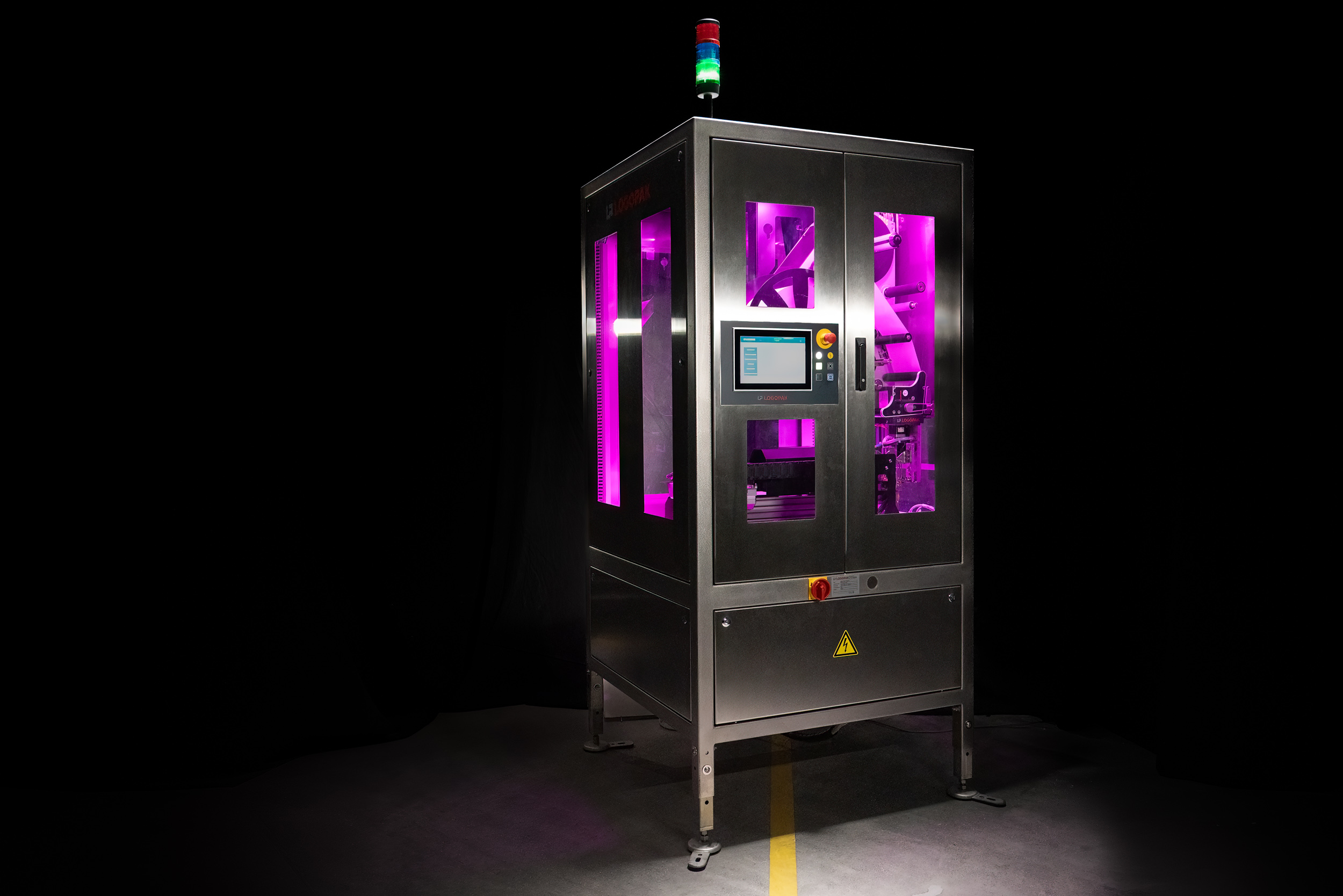

Sustainable pallet labelling: 850 eP3 Hybrid

One highlight is the 850 eP3 Hybrid pallet labelling system, which for the first time operates entirely without compressed air. This enables companies to significantly reduce their energy consumption and carbon footprint – a decisive advantage against the backdrop of increasing regulatory requirements for resource efficiency and climate protection. The system can process either direct thermal or linerless labels without backing material, saving around one tonne of CO2 and considerable amounts of waste per 400,000 labelled pallets (in two-shift operation).

850 eP3 Hybrid: Pallet labelling without compressed air

Linerless or standard labels: one system, complete freedom

The 850 eP3 Hybrid labelling system combines high performance with true material freedom: users can switch between linerless and standard labels. The pallet labelling system operates without compressed air, saves energy, reduces CO₂ emissions – and is perfect for GS1-compliant pallet labelling on three sides.

The benefits at a glance:

- Flexibility thanks to hybrid technology: Processes linerless and standard labels – you decide

- No pneumatics required: 100% electric, no compressed air system required – reduces energy costs and CO₂ emissions

- Less wear and tear, lower maintenance costs, longer service life

- GS1-compliant 3-sided labelling

- Up to 180 pallets per hour

Compact entry-level model: Logomatic 715 PF

The Logomatic 715 PF is designed for companies looking for a space-saving solution for 2-sided labelling. With up to 120 pallets per hour, it is particularly suited to standard applications. Features such as a real-time clock, compressed air monitoring and an integrated article database support efficient processes. Thanks to its reduced footprint and optimised energy consumption, the system fits well into sustainability strategies.

715 PF: Compact 2-sided pallet labelling

GS1-compliant, efficient & space-saving – the entry point into automated pallet labelling

The 715 PF labelling system offers an economical solution for GS1-compliant pallet labelling on two sides – with minimal space requirements. Ideal for standard applications with high throughput, small footprint and full functionality ex works. For efficient production lines with a focus on reliability and cost control.

The benefits at a glance:

- 2-sided pallet labelling according to GS1 – up to 120 pallets per hour

- Compact design – requires only a small footprint

- Integrated article database – can also be used in offline/stand-alone mode

- Standard features include error diagnosis, real-time clock and compressed air/vacuum monitoring

- Modular expansion options – e.g. with scanner, height adjustment or barcode validation

- Optimal price-performance ratio for standard labelling in the tertiary sector

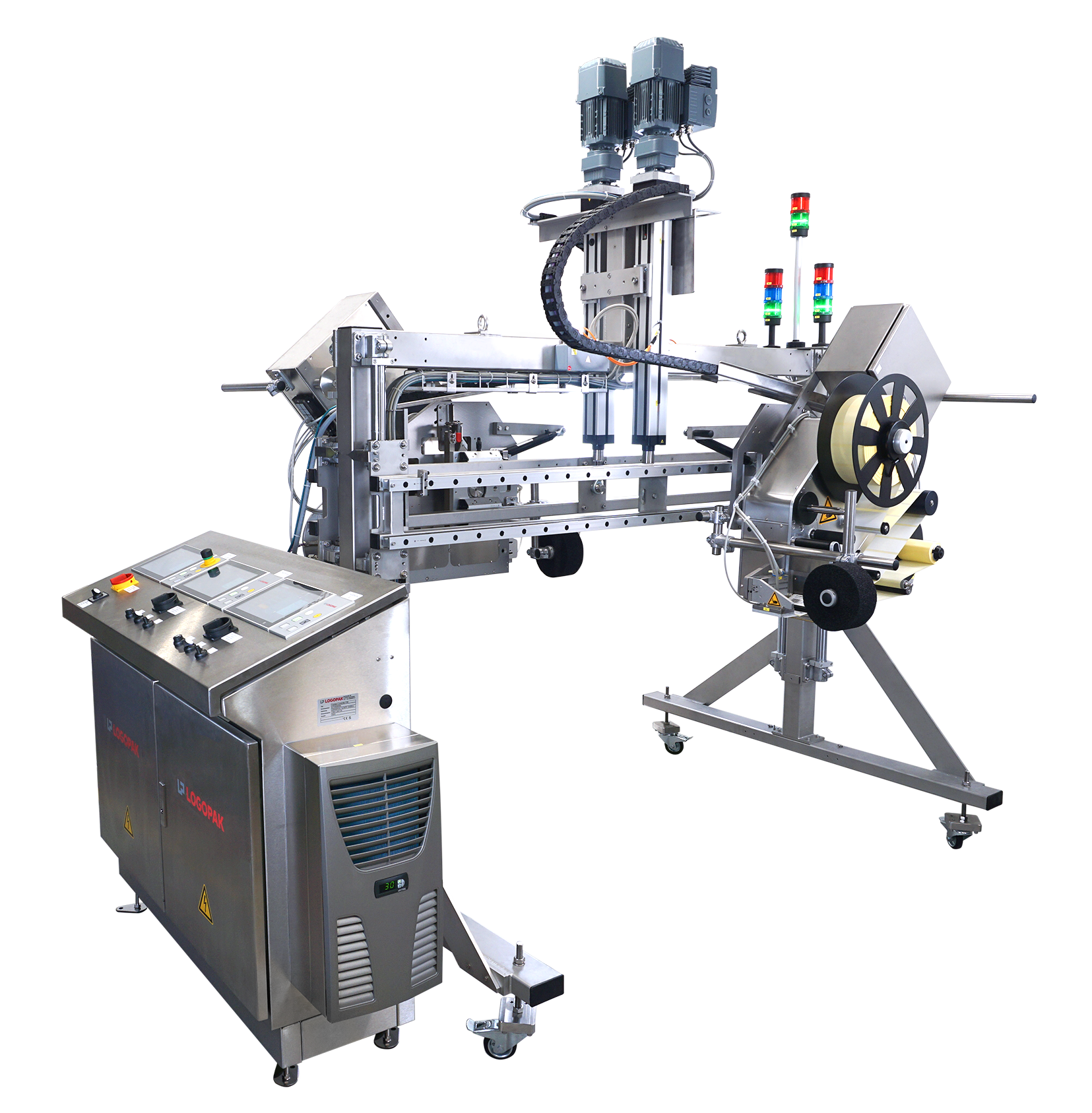

Residue-free labelling with cord: 850 PSC

Logopak presents the 850 PSC cord labelling system for reusable beverage crates. It attaches labels to a reusable cord made from recycled fibres. This completely eliminates the need for plastic bands and adhesive residues. This facilitates the return of crates, saves resources and supports companies in implementing circular economy concepts in accordance with PPWR requirements.

850 PSC: Cord labelling system for sustainable pallet labelling with linerless labels

Residue-free labelling – efficient, sustainable and flexible

The 850 PSC labelling system enables environmentally friendly, residue-free labelling of pallets by attaching the labels to a reusable cord made from recycled textile fibres – ideal for companies that value efficiency and sustainability.

The benefits at a glance:

- Residue-free labelling: Folded-over label only sticks to itself – no adhesive residue.

- Sustainability: Cord made from recycled textile fibres, linerless labels from controlled sustainable sources.

- Efficiency: Cord and label fixed in a single step.

- Flexibility & performance:

- One label: approx. 120 pallets/hour

- Two labels: (front/side): approx. 90–100 pallets/hour

- Two labels: (side/rear): approx. 100–110 pallets/hour

- Three labels: (front/side/rear): approx. 70 pallets/hour

Maximum availability through tandem labelling

The new Logomatic tandem system from the 500 series enables uninterrupted labelling even during roll changes or maintenance. Two units work alternately or in parallel. For production lines with high throughput, this means maximum availability combined with optimised material usage.

Tandem labelling system

for labelling trays and other containers

The benefits at a glance:

- Redundancy: Alternating operation prevents downtime.

- Uninterrupted production: Roll changes or maintenance possible without interrupting the production flow.

- High speed: Up to 180 containers/minute in alternating operation.

- Flexible adjustment: Height and side adjustment, quick changeover between top and side labelling.

- Precision: 100% code checking for error-free labelling.

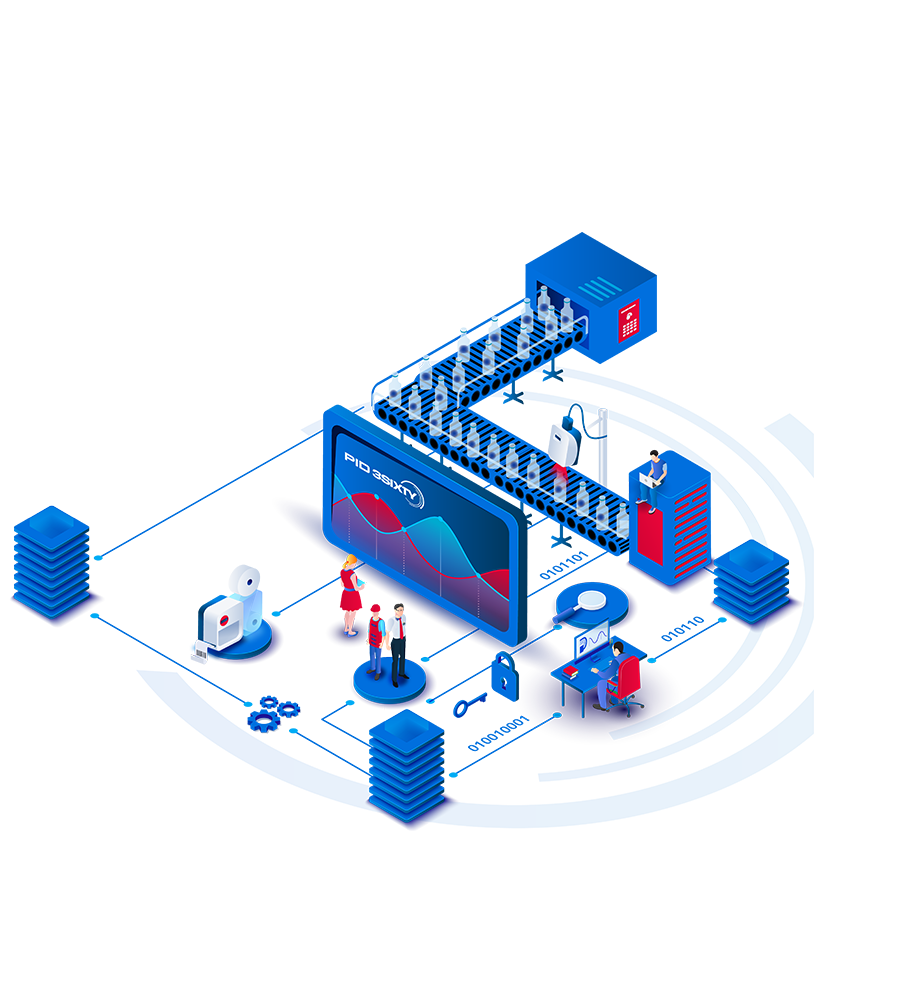

PID 3SIXTY software platform: data management and traceability

In addition to hardware, Logopak presents the PID 3SIXTY software with manage.ID and monitor.ID. It supports automated data transfer from ERP/MES systems, standardised print layouts and live monitoring of machine statuses. This enables seamless batch traceability, reduces downtime and efficiently fulfils legal documentation requirements.

PID 3SIXTY: Control & Management Software – full control over your labelling

Transparency, traceability, compatibility

PID 3SIXTY makes your labelling processes visible, controllable and reliable – across locations and brands. The software provides a complete 360° view in real time and enables seamless traceability across all production lines. This allows you to ensure quality, avoid downtime and measurably increase your line performance.

The benefits at a glance:

- Complete transparency and seamless traceability

- Compatible with all printers – regardless of brand and technology

- 360-degree view of your labelling processes

- Centralised management of layouts, data and processes

Logopak and PID: Independent within a strong alliance

Logopak Systems GmbH & Co. KG is a global leader in industrial labelling systems. Founded in 1978 in Hartenholm, near Hamburg, the company now employs over 300 people across nine locations worldwide. Approximately 80% of its labelling solutions are manufactured at its headquarters.

Logopak is part of Possehl Identification Solutions (PID), a division of the Lübeck-based Possehl Group. This international business unit comprises around a dozen independent partners specialising in labelling, coding, software, and label production. By pooling their extensive expertise and supporting each other in projects, these partners create synergies and added value for their customers while maintaining flexibility and independence. Logopak exemplifies this approach with its claim: "Faster. Safer. Greener."