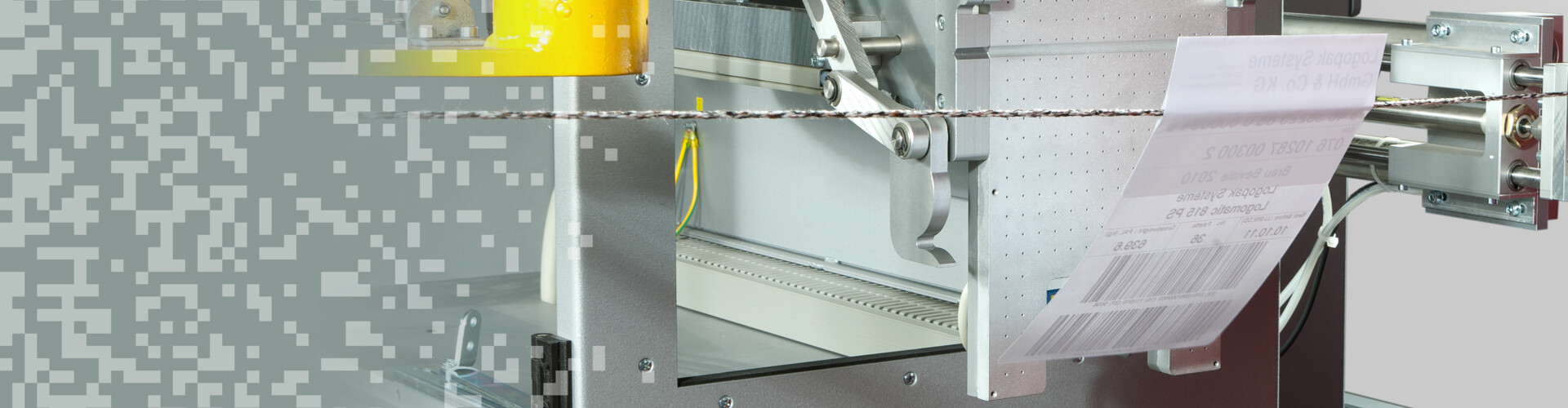

Hartenholm, November 2024 – For the first time at the BrauBeviale trade fair, Logopak Systeme presents its innovative Logomatic 850 PSC cord labelling system, designed for residue-free labelling of pallets with returnable beverage crates. Labels dispensed by the system are attached to a reusable cord made of recycled textile fibres. Alongside enhanced process efficiency – the label is affixed during the strapping process in a single step – the Logomatic 850 PSC contributes significantly to sustainability by eliminating the need for plastic straps to secure labels. Moreover, reusable crates are free from label material and adhesive residue after use. The use of linerless labels made from responsibly sourced materials can prevent any waste from backing material and minimise the CO₂ footprint of labelling processes.

Breweries, mineral water producers, and beverage manufacturers who secure their robust, standardised, and stackable returnable crates on pallets with string are ideal candidates for the Logomatic 850 PSC. However, the system is equally suitable for labelling in industries beyond beverages, wherever stable packaging such as boxes or crates are palletised as flush, uniform stacks and secured with cord.

Labelling and Securing: Dual Functionality Saves Time

The Logomatic 850 PSC is an alternative to the highly successful Logomatic 920 PSCK, which has seen numerous installations since its market introduction in 2013. The new labelling system offers the following performance metrics:

- Labelling with one label: 120 pallets/hour

- Labelling with two labels (front/side): 90–100 pallets/hour

- Labelling with two labels (side/back): 100–110 pallets/hour

- Labelling with three labels (front/side/back): 70 pallets/hour

The system supports A5-sized labels (150 mm x 210 mm) with 65 mm dedicated to folding the label around the securing string, enabling application on up to three sides. This is achieved through a telescopic applicator with 550 mm effective reach and stepless height adjustment, ensuring fast and precise labelling on all required surfaces.

The Logomatic 850 PSC boasts a print speed of 300 mm per second and handles label rolls with lengths exceeding 800 m for extended change intervals. Label roll diameters of up to 400 mm are supported. During operation, printing and application of a single label take under 10 seconds, allowing the system’s dual functionality to deliver significant process time savings. Label readability is verified through a 100% code check directly at the applicator, with automatic replacement of defective labels.

Debuted at BrauBeviale, the Logomatic 850 PSC offers efficient and sustainable labelling solutions for pallets with returnable beverage crates.

850 PSC: Cord labelling system for sustainable pallet labelling with linerless labels

Residue-free labelling - efficient, sustainable and flexible

The 850 PSC labelling system enables environmentally friendly, residue-free labelling of pallets by attaching the labels to a reusable cord made from recycled textile fibres - ideal for companies that focus on efficiency and sustainability.

The advantages at a glance:

- Residue-free labelling: folded label only sticks to itself - no adhesive residue.

- Sustainability: cord made from recycled textile fibres, linerless labels.

- Efficiency: Fixing of cord and label in one operation.

- Flexibilität & Leistung:

- One label: approx. 120 pal./h

- Two labels (front/side): approx. 90-100 pallets/h

- Two labels (side/rear): approx. 100-110 pallets/h

- Three labels (front/side/rear): approx. 70 pallets/h

Logopak Systeme is presenting the new Logomatic 850 PSC cord labelling system for the process-efficient

labelling of pallets with returnable beverage crates for the first time at the BrauBeviale trade fair.

Independent Strength within a Unified Network

Logopak Systems GmbH & Co. KG is a global leader in industrial labelling systems. Founded in 1978 in Hartenholm, near Hamburg, the company now employs over 300 people across nine locations worldwide. Approximately 80% of its labelling solutions are manufactured at its headquarters.

Logopak is part of Possehl Identification Solutions (PID), a division of the Lübeck-based Possehl Group. This international business unit comprises around a dozen independent partners specialising in labelling, coding, software, and label production. By pooling their extensive expertise and supporting each other in projects, these partners create synergies and added value for their customers while maintaining flexibility and independence. Logopak exemplifies this approach with its claim: "Faster. Safer. Greener."