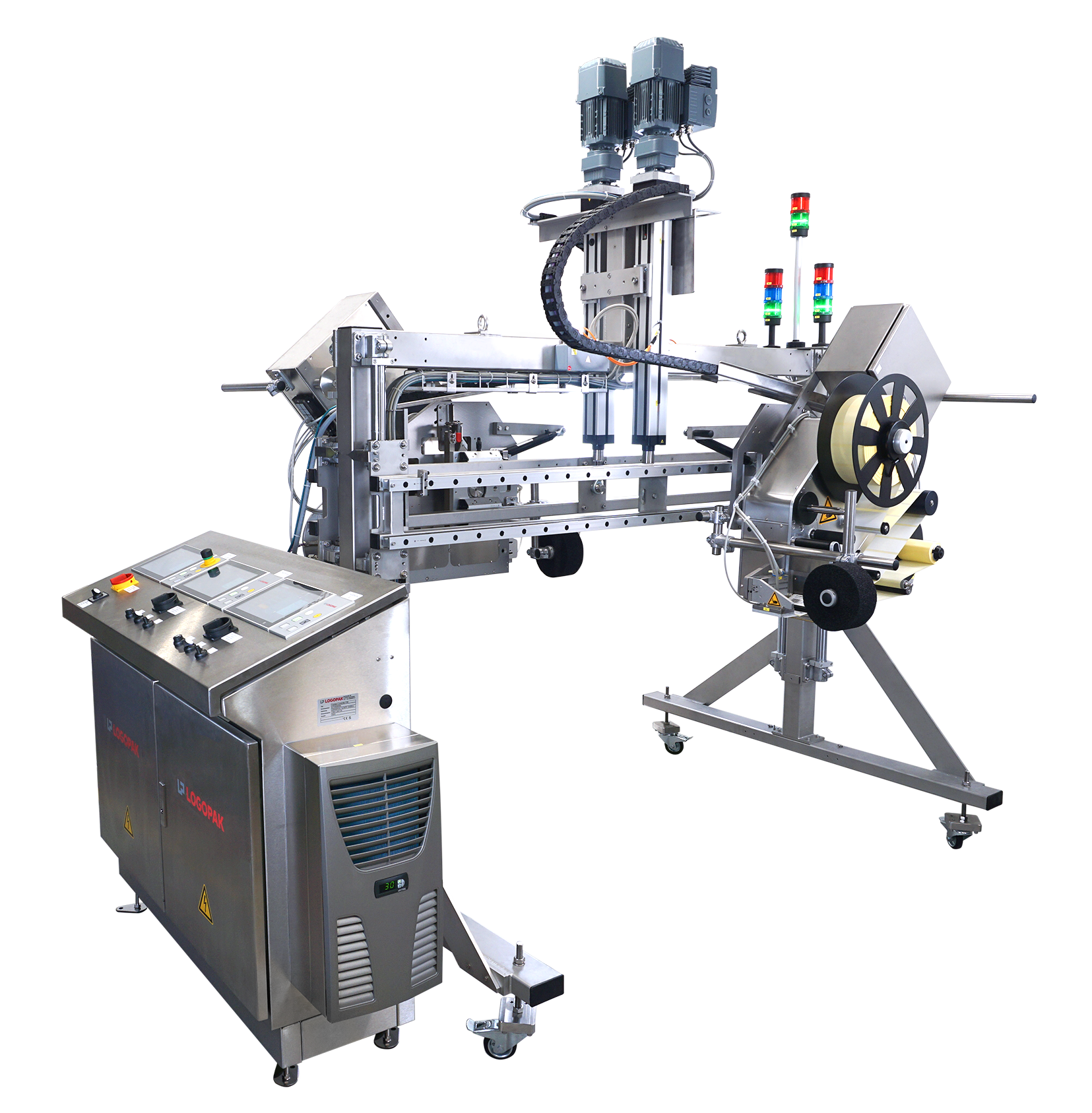

Tandem labelling system

for labelling trays and other containers

The advantages at a glance:

- Redundancy: Alternating operation prevents downtime.

- Uninterrupted production: Roll change or maintenance possible without interrupting the production flow.

- High-speed: Up to 180 packs/minute in alternating operation.

- Flexible adjustment: Height and side adjustment, quick changeover between top and side labelling

- Precision: 100% code check for error-free labelling.

The print data can be selected manually using the coded job number and saved on the labeller - or, alternatively, automatically selected and retrieved in a control system using the PID 3SIXTY software tool available from Logopak. It is also possible to integrate the Logomatic tandem labeller directly into the customer's line control system.

Reliable and production-safe labelling with redundancy system

The Logomatic Series 500 tandem labelling system ensures maximum operational reliability and production continuity through its redundant design, regardless of the operating mode. When operating in alternating mode – where containers are labelled alternately by the two labellers – and one unit reaches the end of its roll, the remaining labeller takes over the labelling of all containers at a reduced conveyor speed until the roll change is complete. This allows production to continue uninterrupted, just as in standby mode, where one labeller marks all containers in a single line, and the second unit seamlessly takes over during roll changes or maintenance. Precise triggering of the labellers is achieved through light barriers, ensuring high repeat accuracy in label positioning on the containers. Barcode scanners integrated near the applicators provide 100% code verification, guaranteeing machine-readable labels.

Flexible adaptation to diverse labelling scenarios

The Logomatic Series 500 tandem labelling system offers exceptional flexibility to adapt to various on-site application scenarios. Features such as an electric height adjustment with a key switch and emergency stop button, manual side adjustment, and a toggle switch for setting the labelling position facilitate this adaptability. Additionally, the portal frame itself can be customised to meet specific customer requirements. Using the tandem controller’s control panel, customers can adjust the operating mode to suit their individual labelling needs, process requirements, and throughput targets, as well as access additional features such as gap monitoring. For installations requiring multiple labelling systems, the functionality of the tandem controller can be expanded into a multi-controller.

Logopak und PID: Eigenständig in einem starken Verbund

Logopak Systems GmbH & Co. KG is a global leader in industrial labelling systems. Founded in 1978 in Hartenholm, near Hamburg, the company now employs over 300 people across nine locations worldwide. Approximately 80% of its labelling solutions are manufactured at its headquarters.

Logopak is part of Possehl Identification Solutions (PID), a division of the Lübeck-based Possehl Group. This international business unit comprises around a dozen independent partners specialising in labelling, coding, software, and label production. By pooling their extensive expertise and supporting each other in projects, these partners create synergies and added value for their customers while maintaining flexibility and independence. Logopak exemplifies this approach with its claim: "Faster. Safer. Greener."