The future of labelling

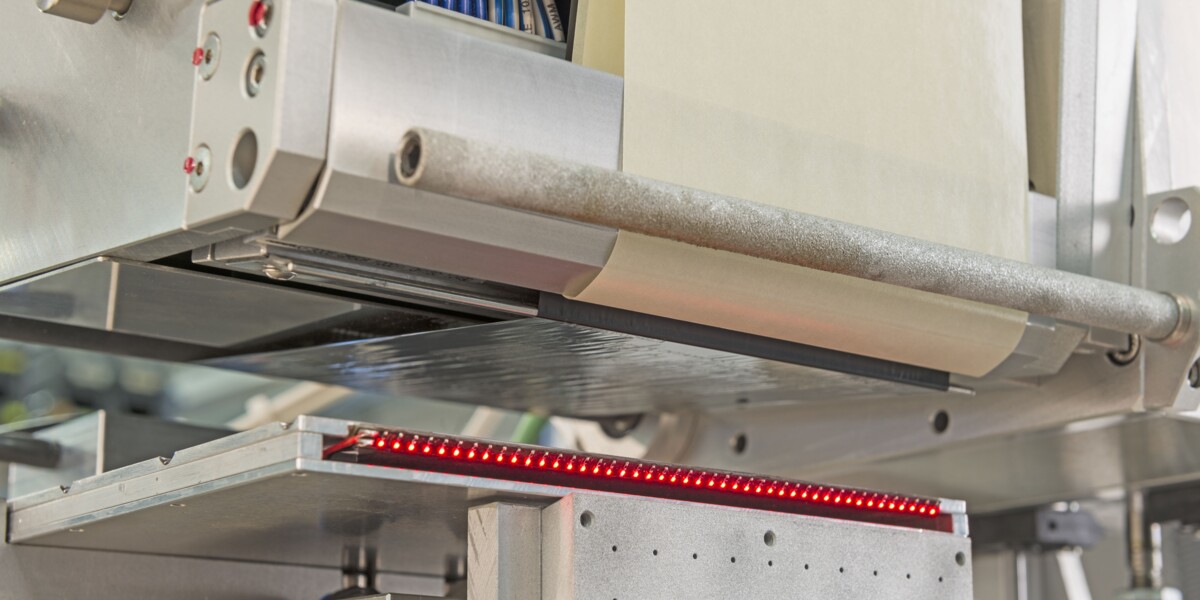

Everybody is talking about the future. We give it an identity.As pioneers in the field of industrial labelling, we have been committed to supporting industrial clients in developing future-oriented production and logistics processes for over 40 years. We create sustainable added value for our customers. Our labelling solutions guarantee more efficiency and safety, increased availability, and, most importantly, more sustainability.