Optimal labelling solutions for the Shipping, Logistics and E-Commerce Industry

Easy to integrate and customisable to your needsCharacteristic features

- Continuous operation at high cycle rates

- Speed and efficiency

- Traceability of goods

Challenges

- Data security and product identification

- Speed and real-time labelling

- Different packaging materials

Our solutions

Increased speed:

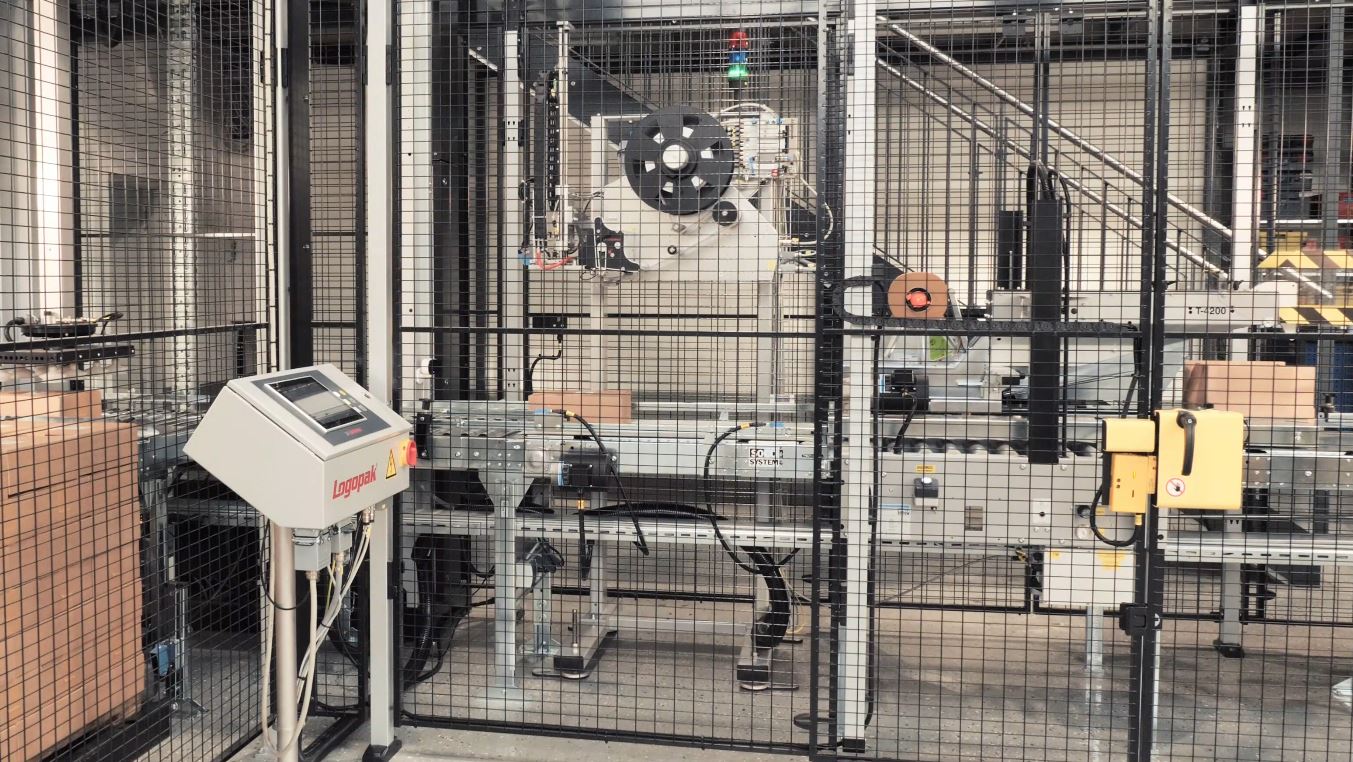

- Fast and flexible print & apply systems (cyclic and throughput operation) for shipping cartons, pallets, lattice boxes, and other large-volume charge carriers.

- Real time labelling at maximum cycle rates: up to 160 labels per minute applied to cartons and packages.

- Flexible application of standard shipping labels, document pouches for delivery notes and invoices, or OSL labels.

More safety:

- Safe and traceable pallet labelling with GS1 and SSCC barcode labels (one-stop application on two sides for best possible visibility).

- Intelligent data management with PID 3SIXTY for real-time labelling and serial labelling etc. (can easily be integrated in ERP systems).

- Complete product traceability through smart RFID labelling.

- Maximum machine availability: our systems are designed for continuous 24/7 operation

Improved quality:

- Unique feature: high-end quality control with our patented Logopak Vericoder

- TDI touch screen ensures easy and efficient machine operation

- 1D and 2D barcodes in real time provide a higher information density and optimal traceability

Increased sustainability:

- Less material, lower CO₂ emissions and zero waste through linerless labelling.

- Energy-saving electric drive of the labeller and environmentally friendly processes.

Practical applications

Shipping label application / Mail-Order

- Labelling at standstill

- Labelling in tandem operation

- Different product heights

Shipping label application / linerless

- Waste avoidance due to omission of the carrier material

- Longer service life due to 60 % higher material capacity

- Multi-chamber stamp for individual label lengths

Shipping label application

- Identification label scanning

- Handling of data flows/ data processing

- Varying product heights

Shipping bag labelling

- Printing of delivery notes and synchronisation with shipped items and packing lines

- Real time labelling of shipping bags

- Printing of shipping labels and cyclic application to shipping bags