Optimal labelling solutions for the Pharma Industry

Easy to integrate and customisable to your needsCharacteristic features

- Highest demands in terms of hygiene and precision

- Fully automated production for maximum process reliability and safety

- Sensitive substances and packaging

Challenges

- Falsified Medicines Directive 2011/62/EU: Tamper-Evident labels

- Guaranteeing process reliability and safety

- Various different sizes, surfaces and packaging formats

Our solutions

Increased speed:

- Both our off-line and in-line labellers ideally complement every production line (complete and easy integration in ERP systems).

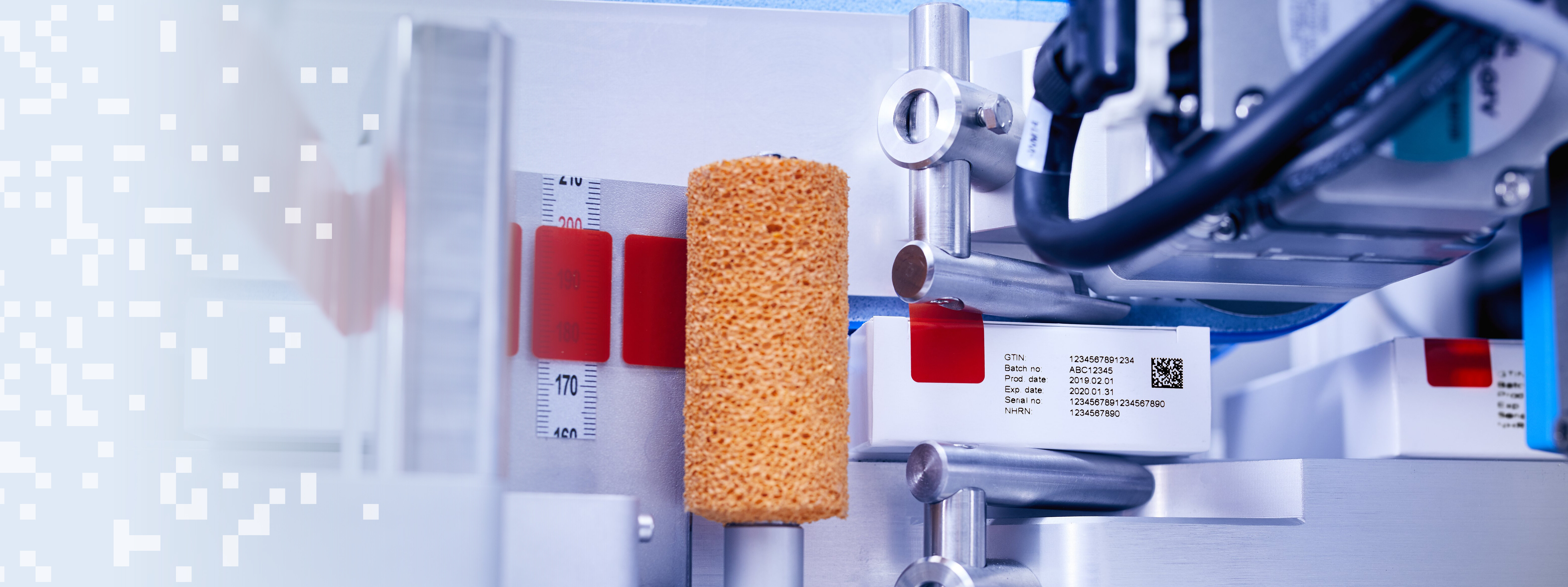

- Highly reliable and easy-to-use vial labellers provide gentle labelling of vials, ampoules, and small cylindrical products: up to 400 units per minute.

- Safe, easy-to-use in-line- and off-line systems provide highly accurate labelling of round, conical and triangular pins and devices: up to 100 products per minute.

More safety:

- Printing of serial numbers / batch data using ink jet or laser technology to ensures best possible compliance security.

- Complete traceability of all articles through smart RFID labelling.

- GAMP-compliant cardboard packaging in accordance with the Falsified Medicines Directive 2011/62/EU (Tamper-Evident labels), and highest levels of process reliability and safety.

- Secure closing and sealing of packaging, with transparent or non-transparent labels.

Improved quality:

- Unique feature: high-end quality control with our patented Logopak Vericoder.

- In-line labellers provide high-precision application on syringes: up to 200 products per minute with millimetric label accuracy.

- Automated discharge system for non-conforming or faulty products.

- Heavy-duty systems with robust enclosures, high cycle rates and reduced material changeover times

Increased sustainability:

- Less material, lower CO₂ emissions and zero waste through linerless labelling.

- Energy-saving electric drive of the labeller and environmentally friendly processes.

Practical applications

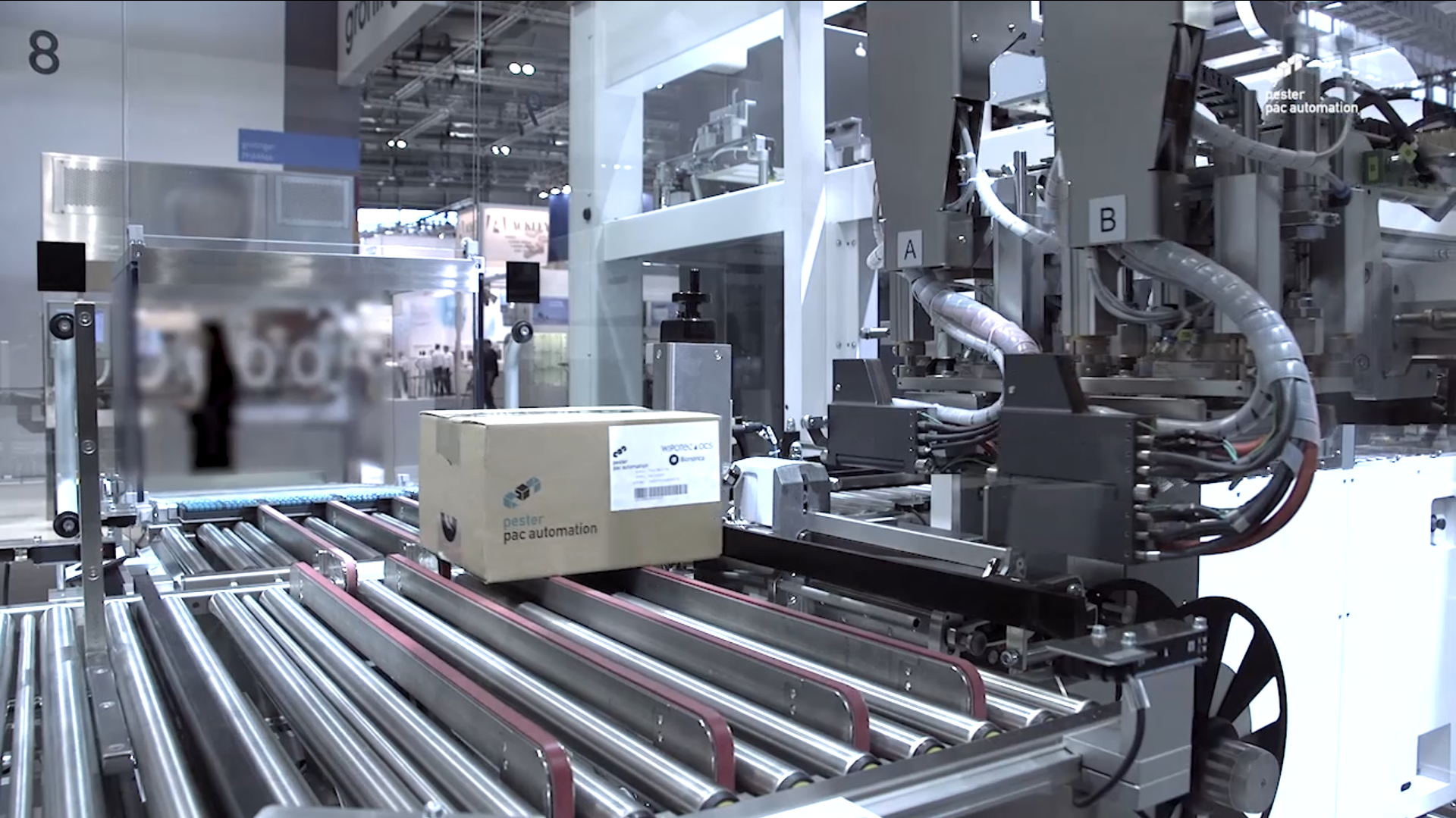

Shipping label application

- Greener labelling through linerless technology

- Two-side high-speed labelling