Optimal labelling solutions for the Food Industry

Easy to integrate and customisable to your needsCharacteristic features

- Food safety and extremely high hygiene standards

- Traceability of goods

- Information on the date and time of production, batch data, ingredients, use-by date etc.

Challenges

- Compliance with statutory standards and complete tracing & tracking

- Various different surfaces and packaging types

- Perfectly readable labels.

- Extreme production environments (e.g. deep-freeze zones)

- Different cycle rates, from low to very high

- Systems are exposed to excessive strain due to intensive cleaning

Our solutions

Increased speed:

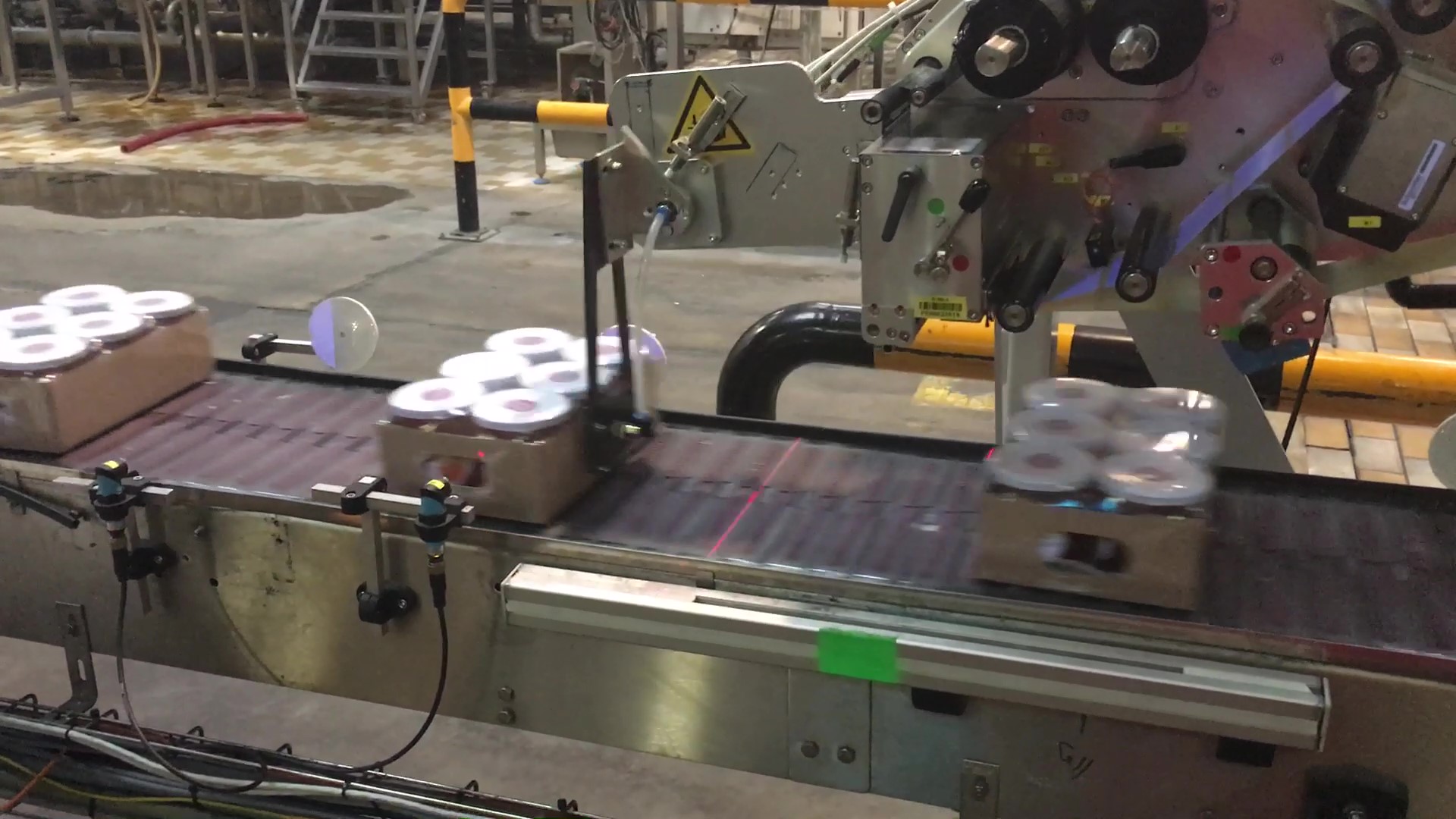

- Fast, high-precision machines for all labelling needs: primary and secondary labelling of trays, cartons and other package types, or pallets and reusable packaging items.

- Print & apply systems with high cycle rates for pass-through secondary labelling with millimetric application accuracy: up to 160 cartons, trays or shrink packs per minute.

- High-speed tray and carton labelling in real time for minimal downtimes: 160 units per minute, ISO-compliant verification.

- Increased productivity: tray labelling in a tandem or tridem set-up with up to 320 or 480 labels per minute.

- Fast, high-precision pallet labelling: up to 240 pallets per hour with applications on up to 3 sides, labels of up to DIN A3 in portrait and landscape format, GS1 standard with EAN128 coding.

Increased safety:

- Tracing & tracking through smart RFID labelling and intelligent data management with PID 3SIXTY.

- Highest availability: designed for continuous 24/7 operation

Improved quality:

- High-precision primary labelling for all surfaces: 160 labels per minute applied onto glass, plastic or metal surfaces, all-round labelling or combined all-round and lid labelling.

- Gentle, contact-free labelling (blow-on system) for pressure-sensitive products.

- Ideal for use in extremely cold environments: insulating enclosure and non-corrosive components for labelling in deep-freeze zones.

- Use of stainless-steel components for hygiene-sensitive areas.

- Outstanding print quality, can be customised to meet your individual requirements.

Increases sustainability:

Less material, lower CO₂ emissions and zero waste through linerless labelling.

Energy-saving electric drive of the labeller and environmentally friendly processes.

Practical applications

Tray labelling, label applied to back of tray

- Labelling (back of tray) in throughput

- Stand-alone labeller with integrated article database

- Uncomplicated integration in existing production line control systems

Tray labelling, label applied to front of tray

- Labelling (front of tray) in throughput

- Integrated barcode scanner

- High-speed front labelling with over 60 labels applied per minute

Tray labelling, label applied to top of tray

- Labelling (top of tray) in throughput

- 24/7 production through redundant labelling systems