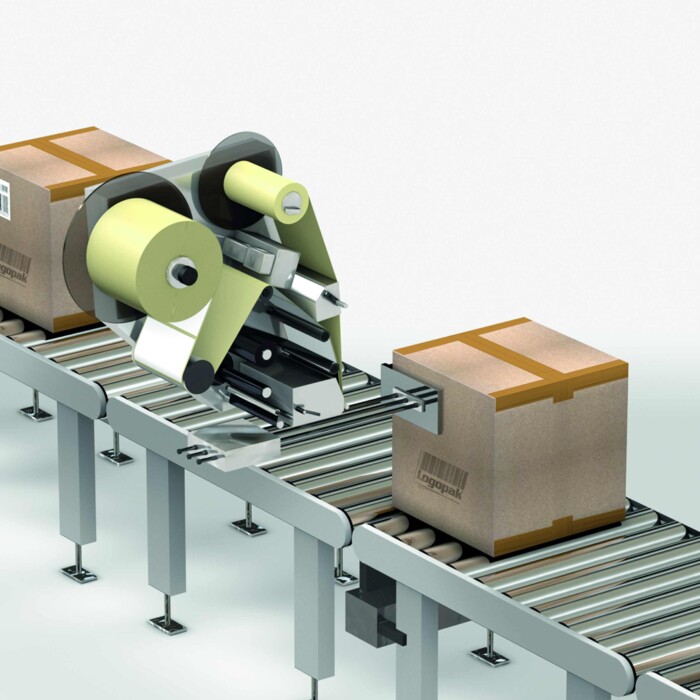

Logopak develops professional labeling systems for the secure programming and application of smart RFID labels. This enables workpieces, tools, products and transport carriers to be automatically identified and localized along the entire value chain at any time - from the first raw material to the sale of the finished product to the end customer. For optimal traceability of your supply chain.

Easily integrated

High speed

Individual solutions

Your benefits

at a glance

- High availability: Designed for industrial 24/7 continuous operation

- Unique and versatile: Support of »Tag-on-Demand«, »Flag-Tags« and »Bad-Tag-Removal«

- Modular: Supports RAIN (GS1, ISO) and HF / NFC standards and individual extensions

- Flexible: All Logopak labeling systems can be equipped with RFID technology - optionally also at a later date

- Reliable : The integration of barcode and RFID labeling in one system ensures secure and faster labeling

- Proven: The Logopak RFID systems have been used successfully for years

Perfect RFID systems for your production

Logopak is an RFID pioneer and expert with over 20 years of application experience. Our industrial RFID goods labeling makes us a valuable enabler and partner for Industry 4.0 and the Internet of Things (IoT). We develop innovative solutions for smart labels, wet inlays and combined barcode and RFID labeling systems in open and closed-loop applications. We work together with our partners AIM, RAIN and GS1 on pioneering technologies that make modern industries even smarter.

Field tested

The Logopak RFID systems have been used in the paper industry for years

Demanding surfaces: on-metal

For RFID labels on metal surfaces

T-Applicator

Die gängigste Methode für die RFID-Etikettierung von Produkten und Paletten

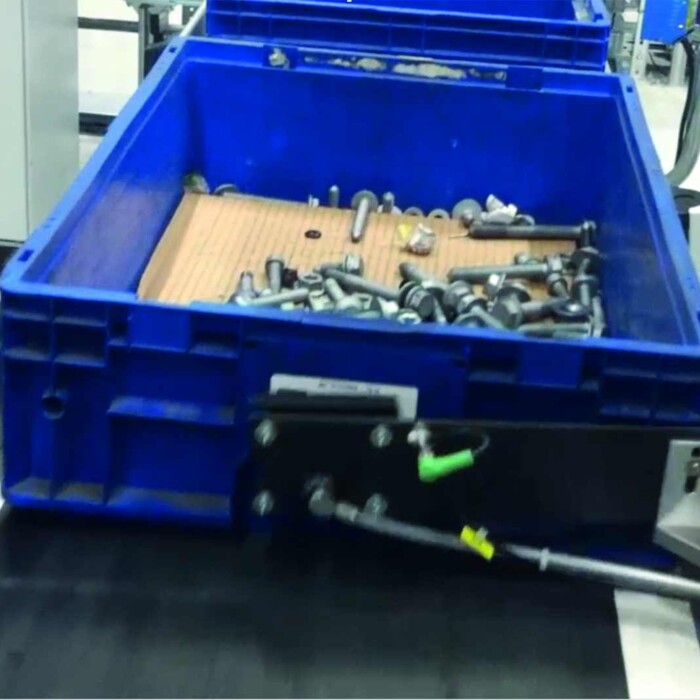

Small load carriers in the automobile industry

RFID labelling of small load carriers without problems

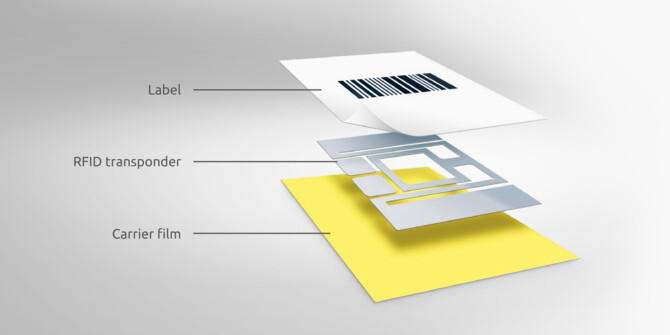

Key technology for supply chains in Industry 4.0 - RFID briefly explained

RFID technology turns mass products into uniquely detectable objects and ensures even faster, more efficient and transparent processes. RFID stands for Radio Frequency Identification, which freely translated means something like "radio identification". An RFID system, consisting of a transponder and a reader, enables technical data to be read and saved without contact.

Seamless traceability and monitoring

Monitor the entire life cycle of your products – from production to delivery. With our RFID labels, you receive automated real-time data for a perfect overview of your stock levels and production processes.

Optimised quality management

Continuous monitoring of products reduces errors and rejects. You save costs and increase customer satisfaction at the same time, because more accurate and faster deliveries allow you to offer your customers a better service.

Download

Flyer: Smarter ID, Smarter Insights: RFID with Sensor Data

An overview of other advantages of RFID technology

- Increased efficiency and optimized work

- RFID makes products smart and capable of communication

- RFID clearly identifies and localizes products - in real time!

- RFID tags with sensors enable dynamic data and record e.g. emperature and humidity

- Contactless recording and efficient exchange of data, also with cooperation partners

- Robust transponders: insensitive to external influences such as dirt or moisture

- Security through passwords against access or rewriting of the RFID tags