Efficient and sustainable labelling systems from Logopak

Your partner for the European Green DealAt Logopak, we are passionate about making your labelling processes more efficient, more secure, and, above all, more environmentally friendly. With the perfect system of excellent hardware, state-of-the-art software and top service. And we help you with smart, transparent documentation for your legal compliance – so that you can realise the goals of the European Green Deal.

Economic efficiency meets sustainability

No liner, no waste, no compromises.

Environmentally friendly, cost-saving e-applicators

Durable machines

Your benefits

at a glance

- Reduced carbon footprint

- Minimised downtimes and maximised output

- Optimised energy consumption thanks to environmentally friendly drives

- Reduced material waste thanks to linerless labelling

- Greater cost-effectiveness thanks to durable machines

- At least 10 years of spare parts availability

Sustainable labels

Linerless labels: labels without waste material

Use our innovative linerless technology for environmentally friendly labelling – without any waste material. Linerless labels enable environmentally friendly labelling, save you money – and score points with excellent legibility.

Secondary labelling

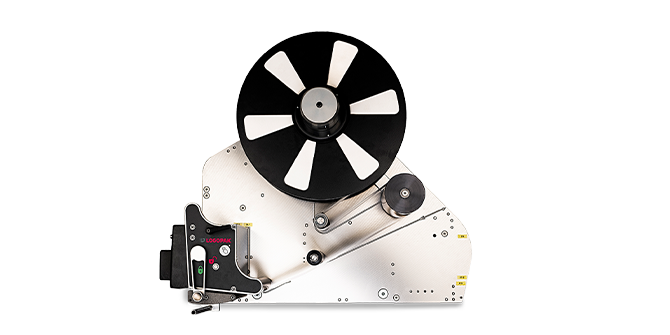

Fully automated labelling system for linerless labels

Perfect symbiosis: Our linerless labels and our 410 Linerless system are the environmentally friendly dream team and bring sustainability to your production line.

Environmentally friendly e-applicator without compressed air

For the icing on the cake: With the gentle 410 Green applicator, you save costs and energy resources and take the sustainability of your labelling to the next level.

Tertiary labelling

to our 850 eP3 Hybrid

to our 850 eP3 HybridHybrid

pallet labellingOur hybrid system with environmentally friendly e-applicator adapts flexibly to your needs: it processes die-cut and linerless labels – just as you need them.

to our 920 PSCK

to our 920 PSCKPallet security cord labelling without backing material

With our fully automated cord labelling system, you can label and secure your pallets in a single step – without PE film!