High-speed labelling of packaging

Maximum efficiency and reliabilitySecondary packaging such as cartons, trays, containers, foil bags, shipping cartons, six-packs etc. encloses and protects products. It is used to group individual articles and repack them to create larger units.

What all the different surfaces and types of secondary packaging have in common is that they need to be labelled speedily and reliably within the production chain, with accurately applied and machine-readable labels printed with product information such as article and batch numbers or use-by dates.

Logopak’s extremely efficient high-speed systems provide reliable secondary labelling in continuous operation. Precise labelling at high cycle rates guarantees highest levels of data security. Automatic height adjustment of the individual packaging items ensures accurate labelling of shipping cartons and shipping bags.

Our labelling systems, which have been specially designed to cater for different requirements (i.e. line speeds, size and positioning of labels, data processing and safety), provide fast and reliable secondary labelling.

Practical applications

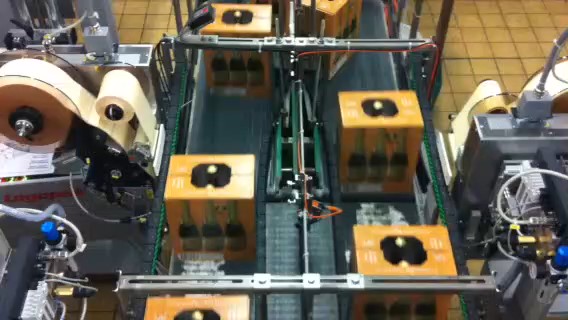

High-speed tray labelling for maximum productivity

For maximum productivity with up to 480 labels per minute applied in real time, provided by our tridem controller and no-contact, blow-on labelling system. Logopak systems require fewer material changes due to our large-capacity label rolls (up to 800m or 1,200m). During material changes, the production continues at reduced cycle rates to minimise downtimes.

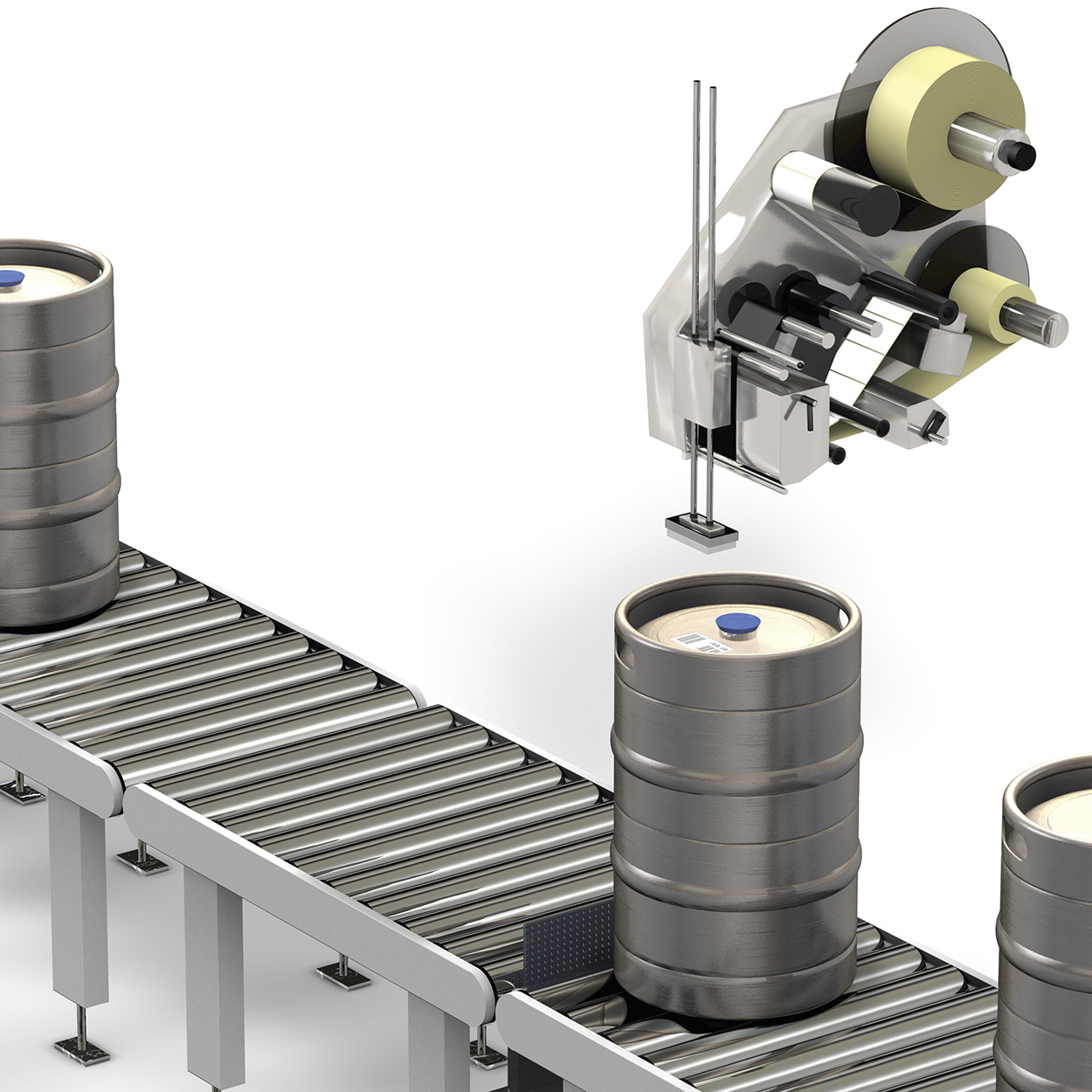

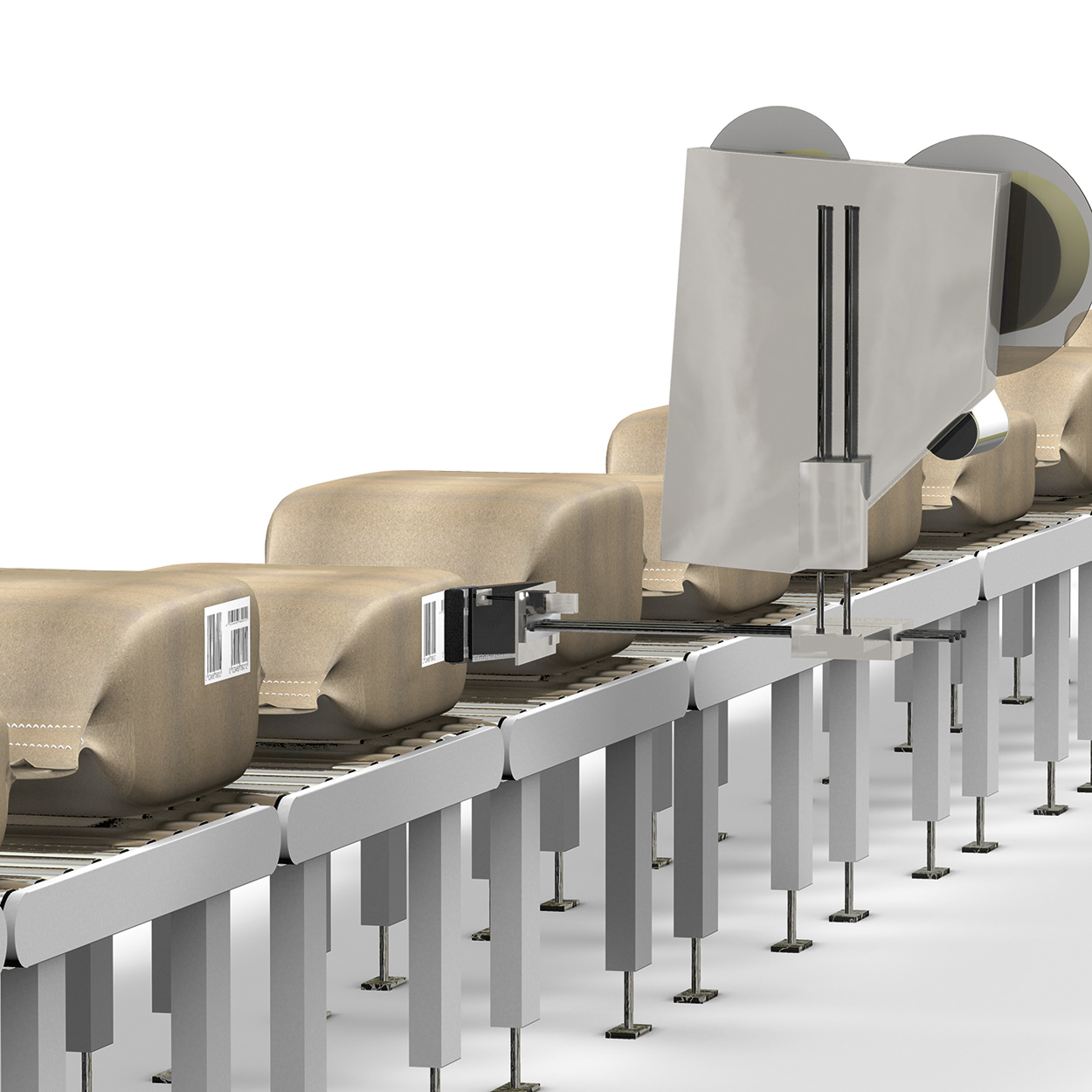

High-speed labelling of packaging units

Logopak systems provide reliable high-speed labelling of packaging units in real time, while our fully automated in-line barcode verification ensures accurately printed barcodes and error-free processes.

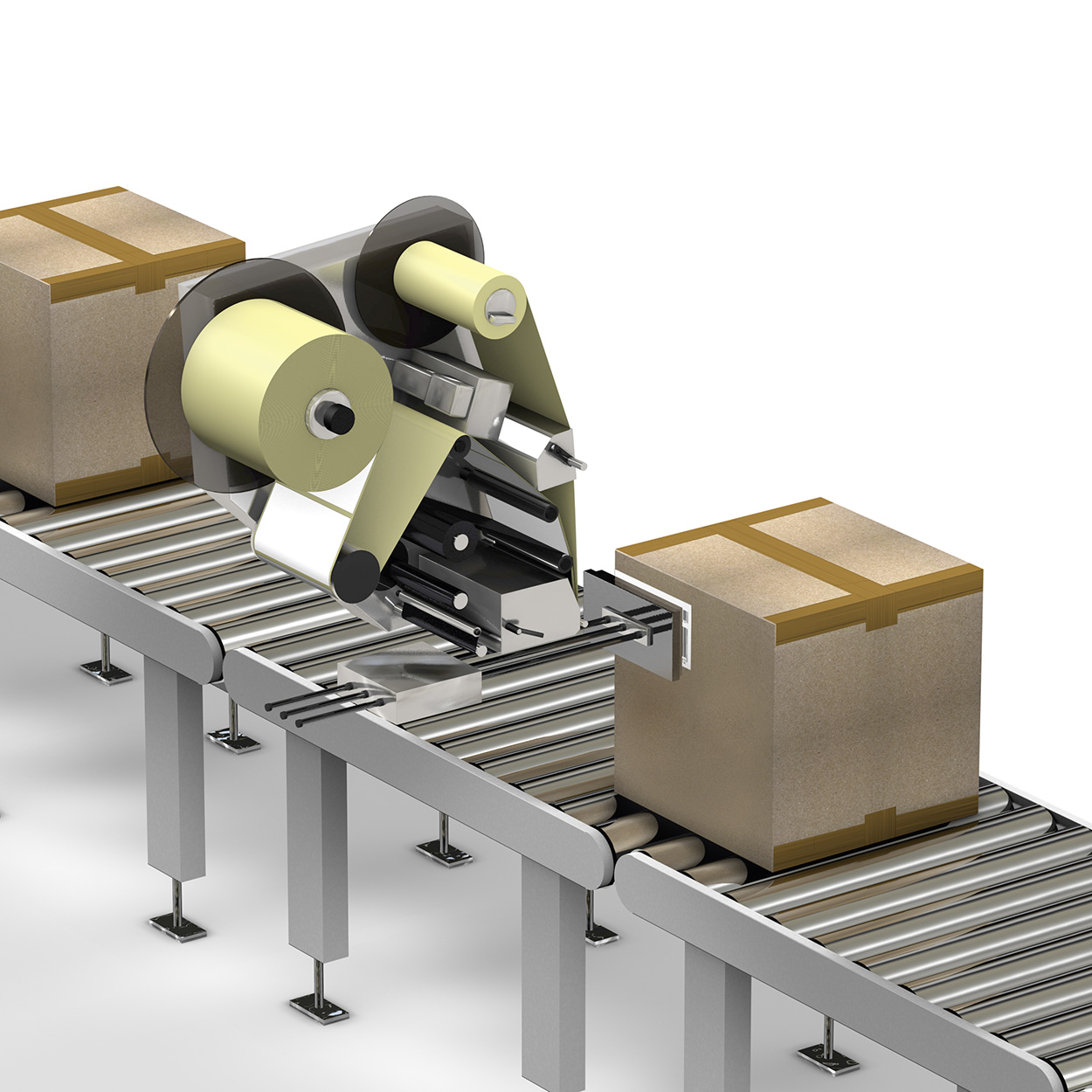

High-speed carton labelling in real time

Providing high-speed labelling in real time, our Logopak systems are tailor-made for the booming e-commerce sector. Automatic height adjustment at high cycle rates ensures continuous labelling with maximum efficiency. In addition, we offer efficient multilateral labelling solutions with labels applied simultaneously to the front and side faces or across corners, or two labels applied with one applicator.

High-speed labelling in the Tobacco industry

Logopak offers Codentify-compliant solutions and applicators for the labelling of cigarette cartons and shipping cartons used in the Tobacco industry. High-precision, no-contact label application and across-corner labelling with reliable quality control for maximum security.

RFID labelling of KLTs in the Automotive sector

RFID labels are applied to small load carriers (KLTs) in order to guarantee complete traceability and ensure efficient intralogistics processes. Logopak solutions provide fast RFID labelling with labels applied variably onto the KLT to VDA and ISO standards.

Gentle and reliable foil labelling

For the labelling of foils or plastic bags, we offer solutions with built-in pressure reducers to avoid damage to the packaging or the product itself. The label is gently yet reliably blown onto the foil or plastic bag via a telescopic system. Logopak systems can be integrated in foil wrapping systems. They swiftly adjust to varying heights and enable labelling of both shipping cartons and foil packaging on the same line.

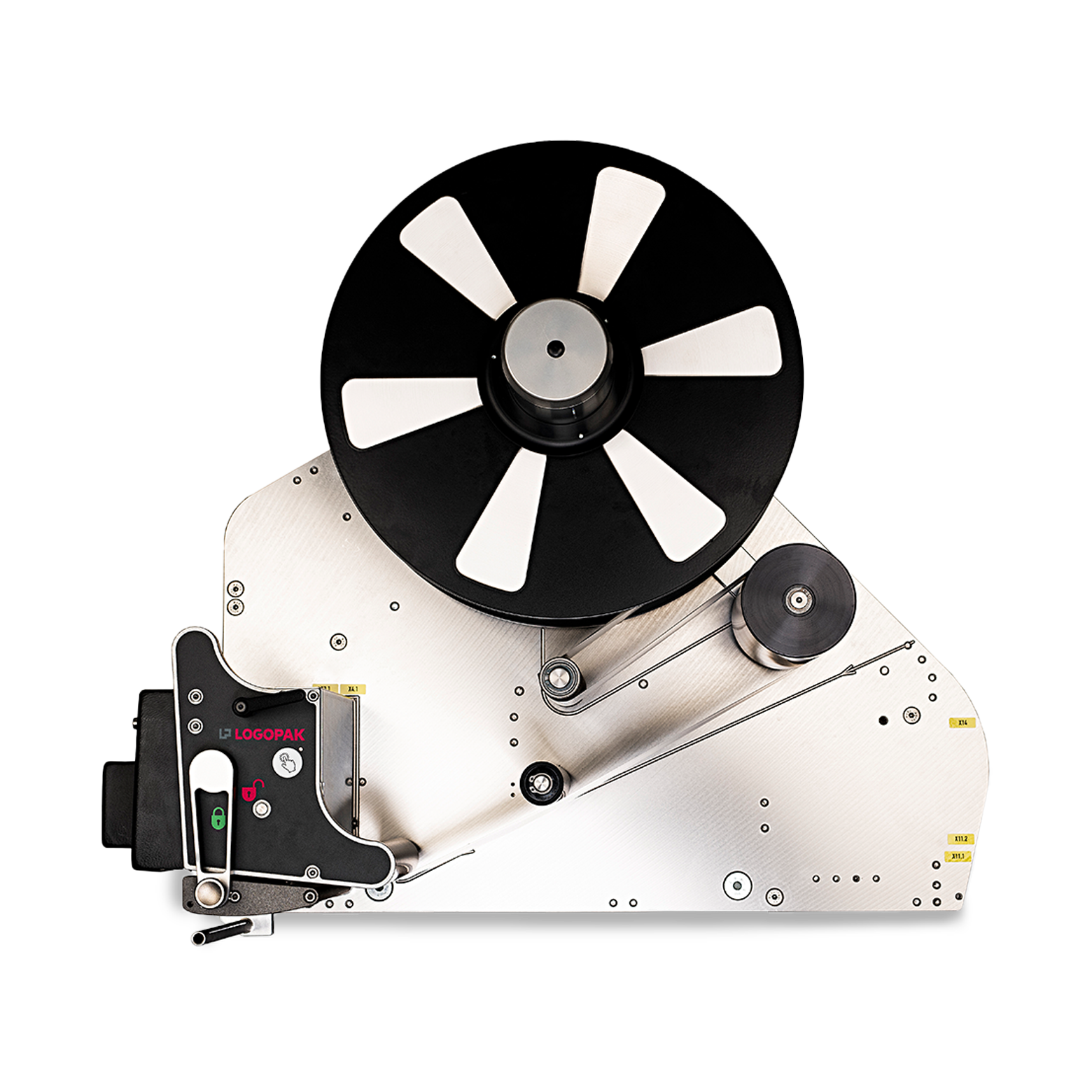

Matching labelling systems

Most widely used applicators

In addition to the space available in individual production facilities, the shape and size of a product are the most decisive factors when it comes to selecting a suitable applicator. Our solutions can be flexibly adapted to almost any product size and easily integrated in individual production environments.