Tailor-made product labelling

For a large variety of surfaces, shapes and batch sizesEach product has its own individual shape, size and surface: round or conical, large or small, smooth or corrugated, made of glass or metal. The challenge and main focus of primary labelling is the precise positioning of pre-printed decorative labels of various shapes and sizes on the product, at high speeds and with high repeat accuracy, and also on particularly difficult surfaces.

Logopak offers a wide range of product- and industry-specific solutions for primary labelling, from pre-printed decorative labels that “sell” the product at the POS mainly through their attractive design, to Tamper-Evident labels and Hazardous Substances labels with additional protection and safety characteristics.

Logopak systems can be easily adapted to different product sizes, and are therefore ideal for companies producing small to medium-size batches with a special emphasis on high-quality processing and maximum system availability.

Practical applications

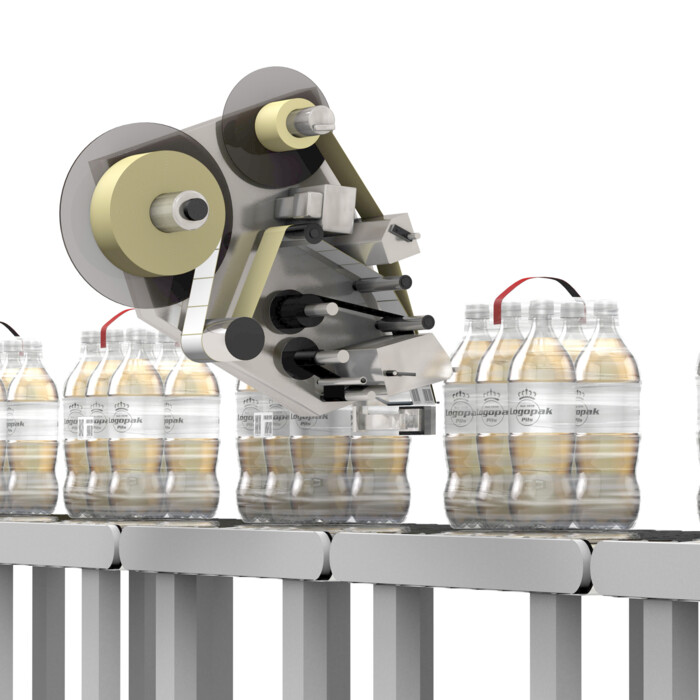

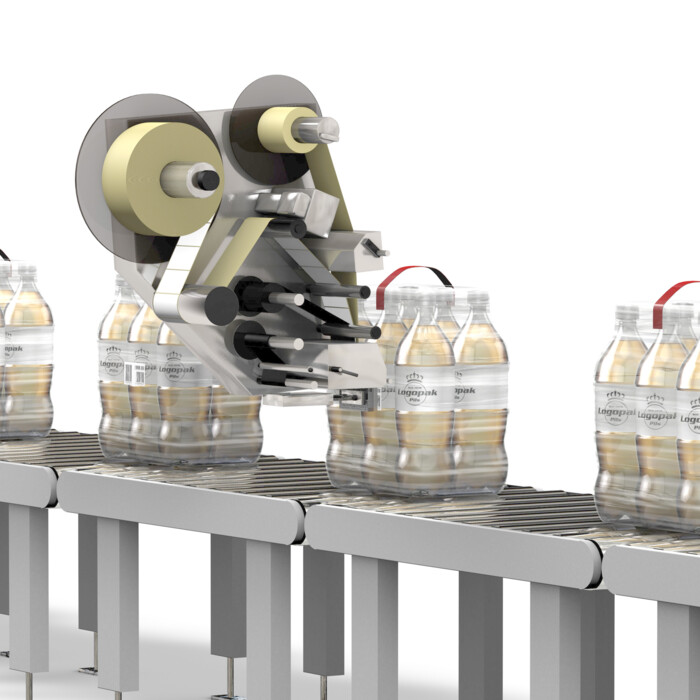

Bottle labelling

Logopak’s highly efficient systems provide all-round labelling of individual bottles and bottle tops in cyclic operation. In particular small and medium-sized breweries as well as delicatessen manufacturers benefit from our smart solutions.

Precise labelling of conical bodies

Our systems ensure fast and accurate labelling (on the lid or all around) of conical and cylindrical products made of glass, plastic or metal. Our special competence of providing flexible and variable labelling of various different shapes and sizes is particularly interesting for the Cosmetic, Pharma, Beverage and Chemical industries. Click here to learn more about our comprehensive industry know-how.

Labelling of large parts for the Automotive industry

Logopak systems with telescopic applicators have been designed especially for the pass-through and RFID labelling of large parts. Durable labels applied to the chassis or the shock absorber ensure complete traceability.

KEG labelling in real time for modern breweries

Logopak’s keg system for modern breweries ensures fast and reliable labelling in real time with up to 15 printed-and-applied labels per minute in cyclic operation. Gained from many years of experience, Logopak has comprehensive expert know-how in the Beverage industry.

Fully automated labelling of parent reels

Our special systems with extra-long applicators make the fully automated labelling of drums and parent reels extremely easy. Whether applied on the side, the top or the front of the reel, or onto paper, corrugated cardboard or non-woven fabric, our industrial systems ensure accurate application of DIN A4 or even DIN A3 labels.

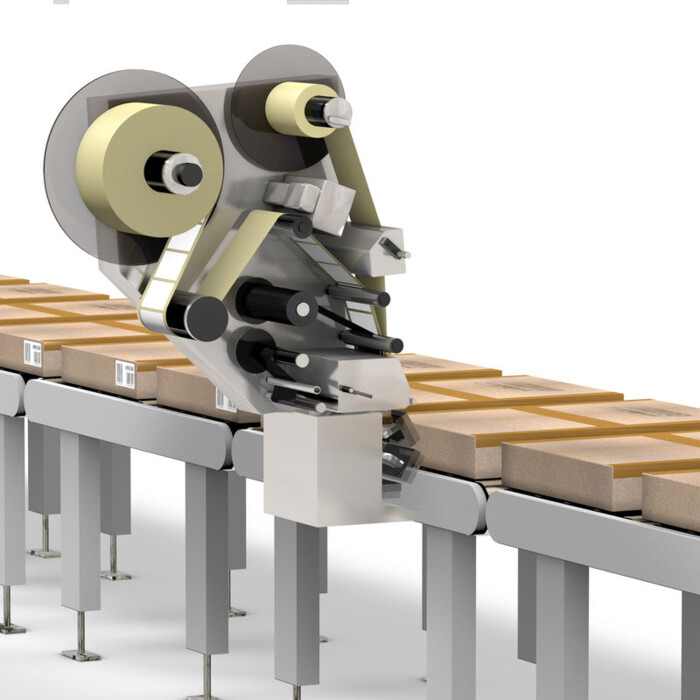

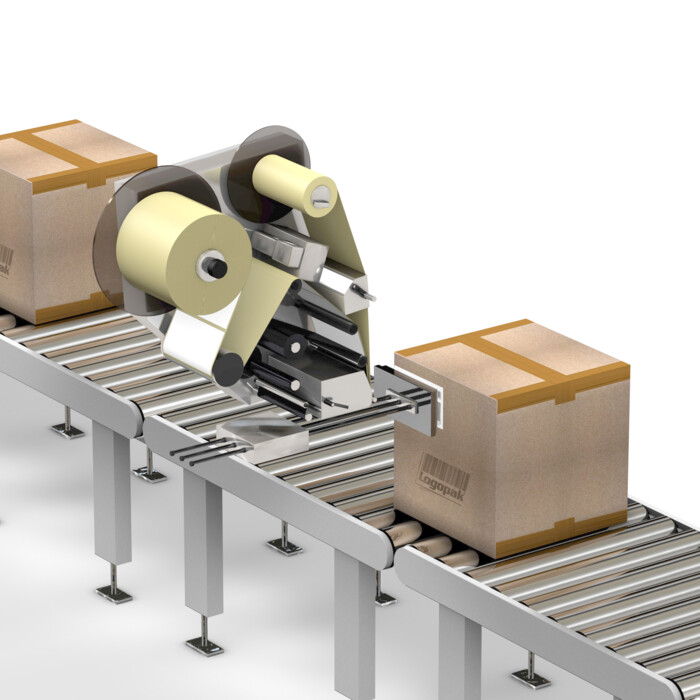

Most widely used applicators

In addition to the space available in individual production facilities, the shape and size of a product are the most decisive factors when it comes to selecting a suitable applicator. Our solutions can be flexibly adapted to almost any product size and easily integrated in individual production environments.

Applicator B90

No-contact, high-speed, blow-on applicator for pass-through applications.

Applicator R

Rotary blow-on applicator for particularly fast, no-contact application with up to 180 cycles per minute with variable data.

Applicator TB

The robust all-rounder: heavy-duty design, with integrated blow-on labelling system for a wide range of applications, for products at variable heights, for pass-through or stationary labelling, can also be used in combination with a product sensor.

Applicator TB-High-Speed

Our high-speed all-rounder: short telescope applicator with vacuum plate and blow-on function for pass-through labelling in real time.