For the highest demands in the industrial sector

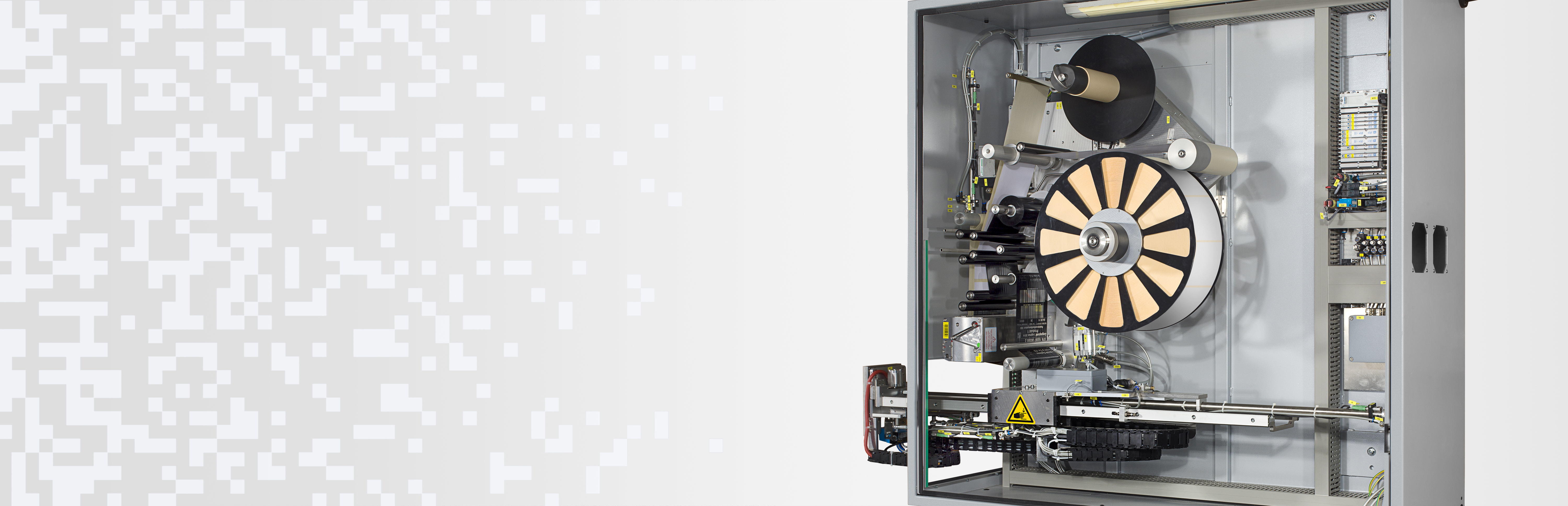

Up to 240 pallets per hour and up to 150 labels per minuteIn a class of its own: With a material running length of up to 1,200 metres, this system is a real endurance runner and prints and applies labels up to A3 – both onto products and pallets. And at a speed of up to 240 pallets per hour. Thanks to the wide range of applicators available, there are virtually no limits when it comes to individual labelling requirements. In short, perfection has a name: Series 900.

Extra-long running times

Smart and efficient

Extremely versatile

The Series 900 in detail

Height and side traverse

Optionally available with height and side traverse. You can set the optimum labelling position manually or automatically. This is practical if you have to label products or pallets of different heights, for example.

Adjustable cooling or heating system

If required, you can equip the enclosure with a cooling or heating system to ensure that the adhesives retain their adhesive strength – for process reliability right down to the last label!

Double head

Fast and powerful: Equipped with a so-called double head, the system can achieve an output of up to 240 pallets per hour.

Your benefits

at a glance

- Top speed (up to 240 pallets/hour)

- Fewer roll changes

- Maximum flexibility

- Robust design (enclosure)

- Intuitive operation via touchscreen

- Print Engine quick-change system

- Direct thermal or thermal transfer printing process for labels up to A5

- Internal database, error diagnostics and many other features

- Works as a stand-alone solution or integrated into your network

Hard Facts:

The Series 900 in figures

- Running length: 1.200 m

- Outer diameter: 400 mm

- Print resolution: 203 or 300 dpi

- Label width: up to 300 mm

- 10" touchscreen

Product labelling application

- Up to 150 labels per minute

- 30 different applicators available (top, front, side, corner)

- Optionally with or without enclosure

Pallet labelling

application

- Up to 240 pallets per hour

- 15 different applicators available (1 to 3-sided)

- Incl. enclosure

Series 900: Models 900 / 920 / 930

We are your partner for sustainable labelling systems

Optimise energy consumption and reduce the carbon footprint of your production with our sustainable labelling solutions – discover them now!

to our sustainable solutions