For maximum speed in industrial environments

Up to 180 pallets per hourOur high-performance high-speed pallet labellers label up to 180 pallets per hour based on GS1 specifications. And – depending on the applicator selected – on up to three sides. Thanks to their compact, modular design and robust mechanical engineering, they are particularly at home in industrial environments.

Fast

High performance

Flexible and reliable

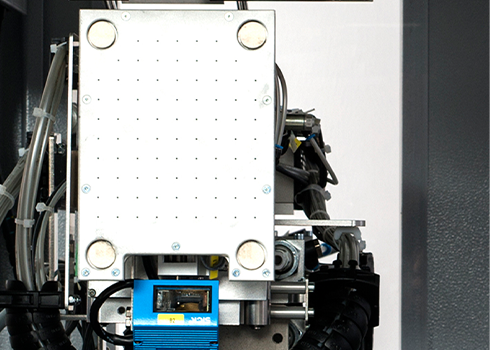

The Series 800 in detail

Enclosure

The particularly robust protective housing is perfect for harsh industrial environments and protects the machine from temperature fluctuations, dust, moisture or heavy impacts.

Many optional extra features

For maximum process reliability: Sensor monitoring during application, an additional stamp that presses the label onto the corners or a scanner that ensures that the barcodes on your product are perfectly legible – simply choose the right option for your requirements.

Labelling of remaining pallets

The last pallet of a batch is not fully loaded, but still needs to be labelled? Simply enter the number of units on the pallet directly on the system display. You can then take the individual label directly from the vacuum plate and stick it onto the pallet. At the same time, the process is transferred to your system by the Series 800 high-speed pallet labeller – with stock accuracy for accurate stock recording.

Your benefits

at a glance

- High labelling performance

- Robust design (enclosure)

- Complies with the GS1 standard

- Intuitive operation via touchscreen

- Simple material change

- Print Engine quick-change system

- Direct thermal or thermal transfer printing process for labels up to A5

- Internal database, error diagnostics and many other features

- Works as a stand-alone solution or integrated into your network

Hard Facts:

The Series 800 in figures

- Running length: 800 m

- Outer diameter: 400 mm

- Print resolution: 203 or 300 dpi

- Label width: up to 165 mm

- Labels up to 180 pallets per hour

- 10" touchscreen

- 4 applicators (1 to 3-sided)

- Incl. enclosure

Series 800: Model 850

We are your partner for sustainable labelling systems

Optimise energy consumption and reduce the carbon footprint of your production with our sustainable labelling solutions – discover them now!

to our sustainable solutions