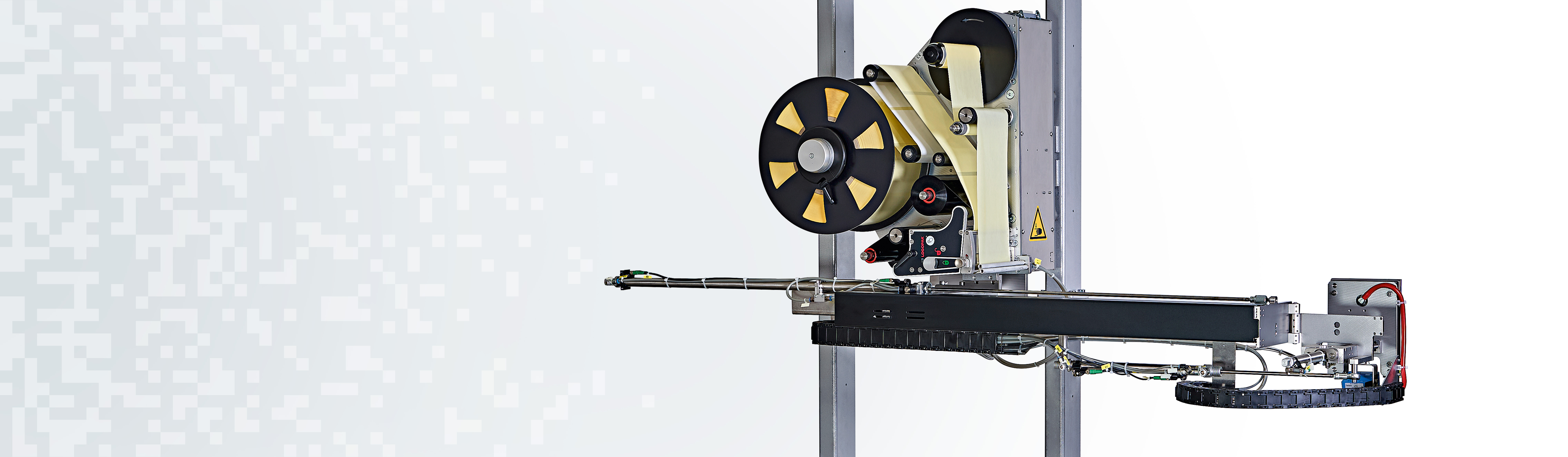

Fully automated pallet labelling

Up to 120 pallets per hourYour ideal entry-level model into the world of pallet labelling! Designed for standard applications, the Series 700 pallet labellers are simple and compact, but provide everything you need for labelling your pallets in proven Logopak quality: up to 120 pallets per hour, depending on the model, on the front and side or on the back and side.

Easy to integrate

Flexible

Cost-efficient

The Serie 700 in detail

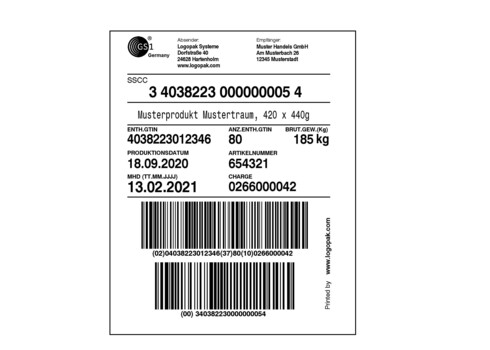

GS1 standard

For labelling pallets in accordance with the GS1 standard – so that the labels sit exactly where they should: On the right-hand half of the pallet on at least one end, and on the long side to the right, with barcode / SSCC, in an area between 400 mm and 800 mm from the floor and with a GS1-compliant prescribed distance of 50 mm from the right-hand side edge.

Generation of SSCC (Serial Shipping Container Code)

For the use of standard A5 labels. Each pallet receives two labels with identical numbers. This number is unique worldwide. The system generates and manages these numbers for you automatically.

Reliable and gentle application

To prevent the applicator from hitting the pallet to be labelled too hard, our applicators have a built-in pressure reducer. This ensures that the labels are applied reliably yet gently. All pressure reducers have a corresponding indicator for visual control.

Your benefits

at a glance

- Suitable for all common standard labelling

- Excellent price-performance ratio

- Complies with the GS1 standard

- Intuitive operation via touchscreen

- Simple material change

- Print Engine quick-change system

- Direct thermal or thermal transfer printing process for labels up to A5

- Internal database, error diagnostics and many other features

- Works as a stand-alone solution or integrated into your network

Hard Facts:

The Series 700 in figures

- Running length: 600 m

- Outer diameter: 350 mm

- Print resolution: 203 or 300 dpi

- Label width: up to 165 mm

- Labels up to 120 pallets per hour

- 10" touchscreen

- Applicator (1 to 2-sided)

Series 700: Models 710 / 715

We are your partner for sustainable labelling systems

Optimise energy consumption and reduce the carbon footprint of your production with our sustainable labelling solutions – discover them now!

to our sustainable solutions