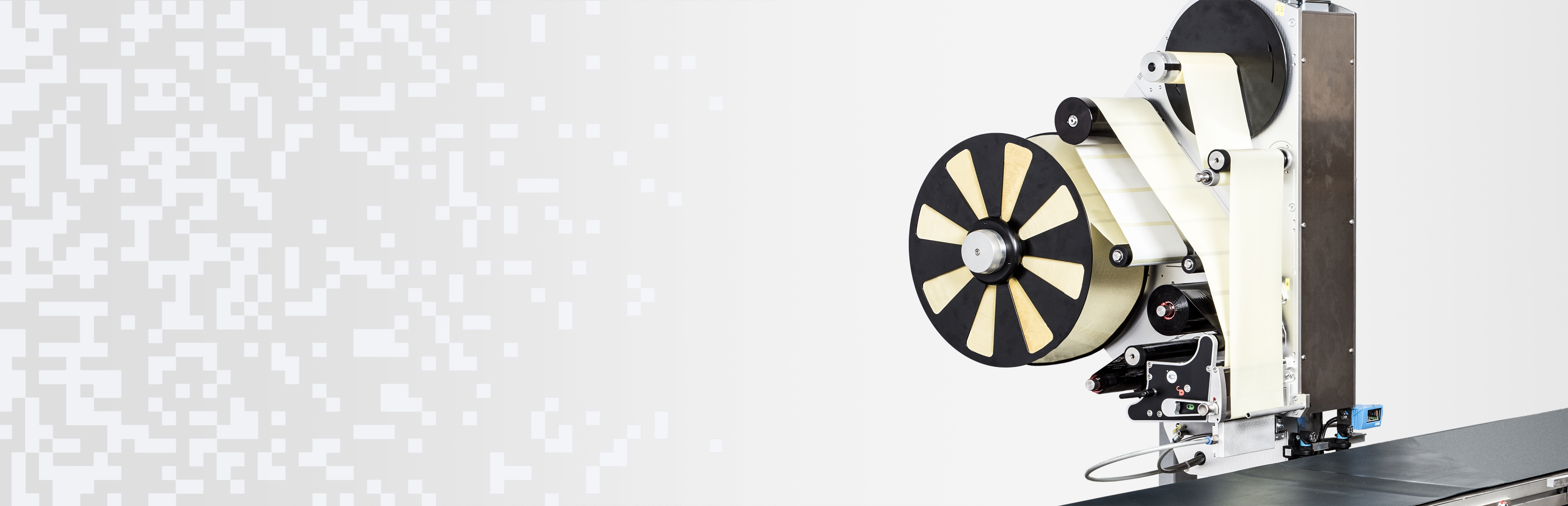

Fully automated high-speed labelling in top quality

Up to 150 labels per minuteHigh cycle rates and an extra-long running length of 800 metres – this is our Series 500, which impresses with fully automated drive technology and fewer roll changes. Thanks to the easy handling of labels and ribbons, the maximum speed product labellers ensure fast, reliable and excellent results in your supply chain.

More running length

Full control in multiple operation

Stable

The Series 500 in detail

Enclosure

The Series 500 is optionally available with an enclosure. This protects the printing unit, label rolls and applicator technology from impacts, temperature fluctuations, dust, moisture and unauthorised access, for example.

Adjustable cooling or heating system

If required, you can equip the enclosure with a cooling or heating system to ensure that the adhesives retain their adhesive strength – for process reliability right down to the last label!

Maximum process reliability and track & trace

An integrated scanner checks the legibility of each label once again after it has been applied. The local database for dispatch units and article data reports all information back to higher-level ERP systems – in real time. For absolute data integrity without any data misalignment!

Your benefits at a glance

- Fast and reliable performance even with high throughput

- Durable and low-maintenance

- High ease of use / simple handling

- 100% electronic control for the best results

- Direct thermal or thermal transfer printing process for labels up to A5

- Internal database, error diagnostics and many other features

- Works as a stand-alone solution or integrated into your network

Hard Facts:

The Series 500in figures

- Running length: 800 m

- Outer diameter: 400 mm

- Print resolution: 203 or 300 dpi

- Label width: up to 165 mm

- 10" touchscreen

- Up to 150 labels per minute

- 30 different applicators available

- Label size up to A5

- Optionally with or without enclosure

Series 500: Models 510 / 515

We are your partner for sustainable labelling systems

Optimise energy consumption and reduce the carbon footprint of your production with our sustainable labelling solutions – discover them now!

to our sustainable solutions