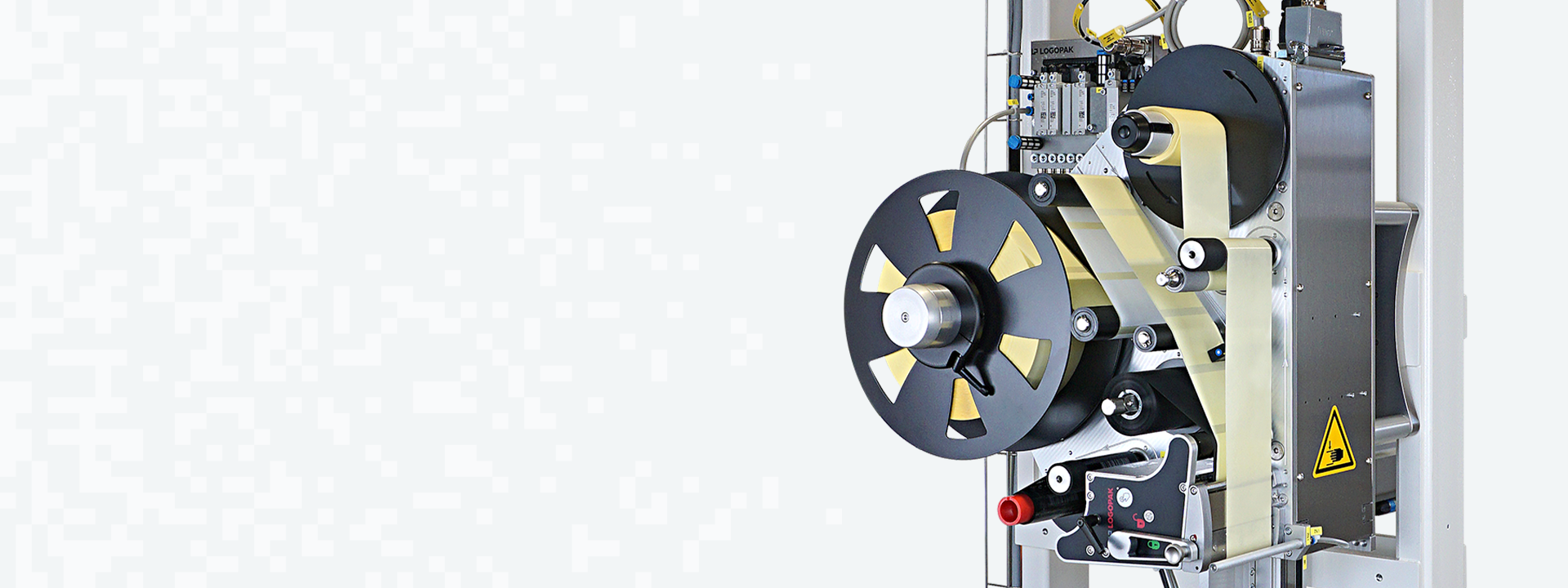

The fully automatic solution for high-speed applications

Up to 120 labels per minuteThis compact print & apply labeller with a small footprint enables high-speed applications with up to 120 applied labels per minute. The high cycle rate makes our high-speed product labeller ideal for particularly demanding industries

High ease of use

Configurable

Low maintenance

The Series 400 in detail

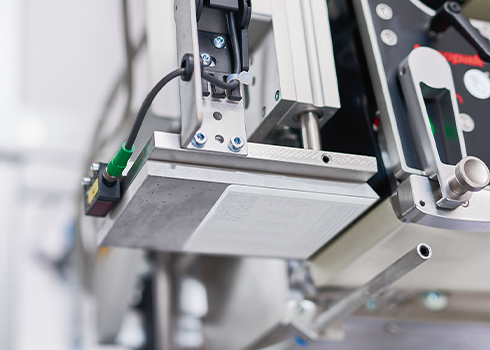

Labelling at standstill or through-feed

Depending on the applicator, the Series 400 can label at standstill or in through-feed. Whichever version you choose, you are guaranteed a high level of process reliability!

Data in real time

The Series 400 prints and applies labels in real time and without label pre-feed. Each label is printed and applied at exactly the right time – ideal for high-speed applications!

Material change

Loading consumables is particularly easy: The open design makes everything easy to reach and enables simple, fast handling.

Your benefits

at a glance

- Fast and efficient

- Durable and low-maintenance

- High ease of use / simple handling

- 100% electronic control for the best results

- Direct thermal or thermal transfer printing process for labels up to A5

- Internal database, error diagnostics and many other features

- Works as a stand-alone solution or integrated into your network

Hard Facts:

The Series 400 in figures

- Running length: 600 m

- Outer diameter: 350 mm

- Print resolution: 203 or 300 dpi

- Label width: up to 165 mm

- Up to 120 labels per minute

- 30 different applicators available

- 10" touchscreen

- Label sizes up to A5

- Enclosure (optional)

Series 400: Models 410 / 415

We are your partner for sustainable labelling systems

Optimise energy consumption and reduce the carbon footprint of your production with our sustainable labelling solutions – discover them now!

to our sustainable solutions