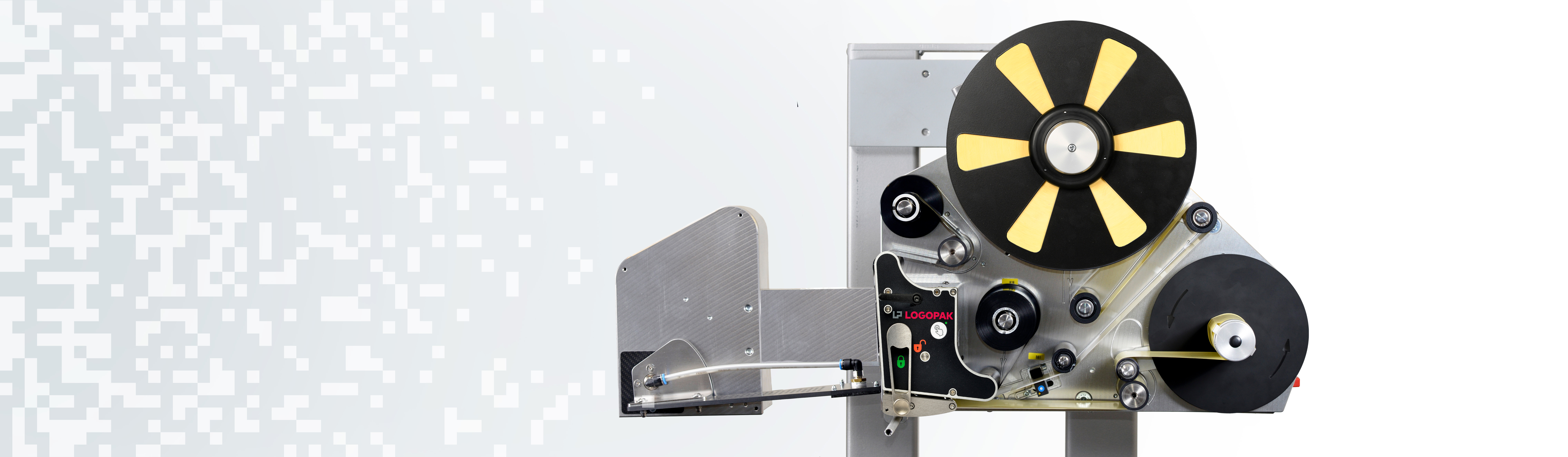

The compact and economical standard solution

Up to 80 labels per minutePerfect for all common standard labelling applications: The system labels up to 80 products per minute – either at the top, side or front. In addition, it is quickly integrated and ready for immediate use, perfect for small and medium-sized companies that want to gain their first experience with fully automated labelling processes.

Easy to integrate

Intelligent

Cost-efficient

The Series 300 in detail

Mobile and flexible

The Series 300 can be re-aligned in height and sideways in just a few simple steps. Practical if you want to label products of different dimensions.

Different versions

For labelling from above, from the side, from the front or combined – for double-sided labelling at the front and on the side. Perfect for your requirements.

Quickly ready for use

Thanks to state-of-the-art software, the product labellers can be used both in line and in stand-alone operation – without a PC or with a connection to your existing software system.

Your benefits

at a glance

- Simple operation

- Quick and easy to set up

- Cost-effective

- Simple material change

- Direct thermal or thermal transfer printing process for labels up to A5

- Internal database, error diagnostics and many other features

- Works as a stand-alone solution or integrated into your network

Hard Facts:

The Series 300 in figures

- Running length: 600 m

- Outer diameter: 350 mm

- Print resolution: 300 dpi or 203 dpi

- Label width: up to 165 mm

- 10" touchscreen

- Available in 4 version (top, side, front and front/side)

- Many applicators to choose from

Series 300: Models 310 / 315

We are your partner for sustainable labelling systems

Optimise energy consumption and reduce the carbon footprint of your production with our sustainable labelling solutions – discover them now!

to our sustainable solutions