No liner, no waste

The environmentally friendly solution for your supply chainOur sustainable linerless product labeller puts an end to waste and unnecessary backing material. With our newly developed linerless labels, you save plenty of waste – and significantly reduce your operating costs and CO2 emissions. You also get around 50 % more labels per roll, for fewer roll-changing stops and significantly longer running times. Hence, in addition to sustainability, the Linerless Series also offers economic benefits.

Environmentally friendly

Seamless labelling

Excellent print results

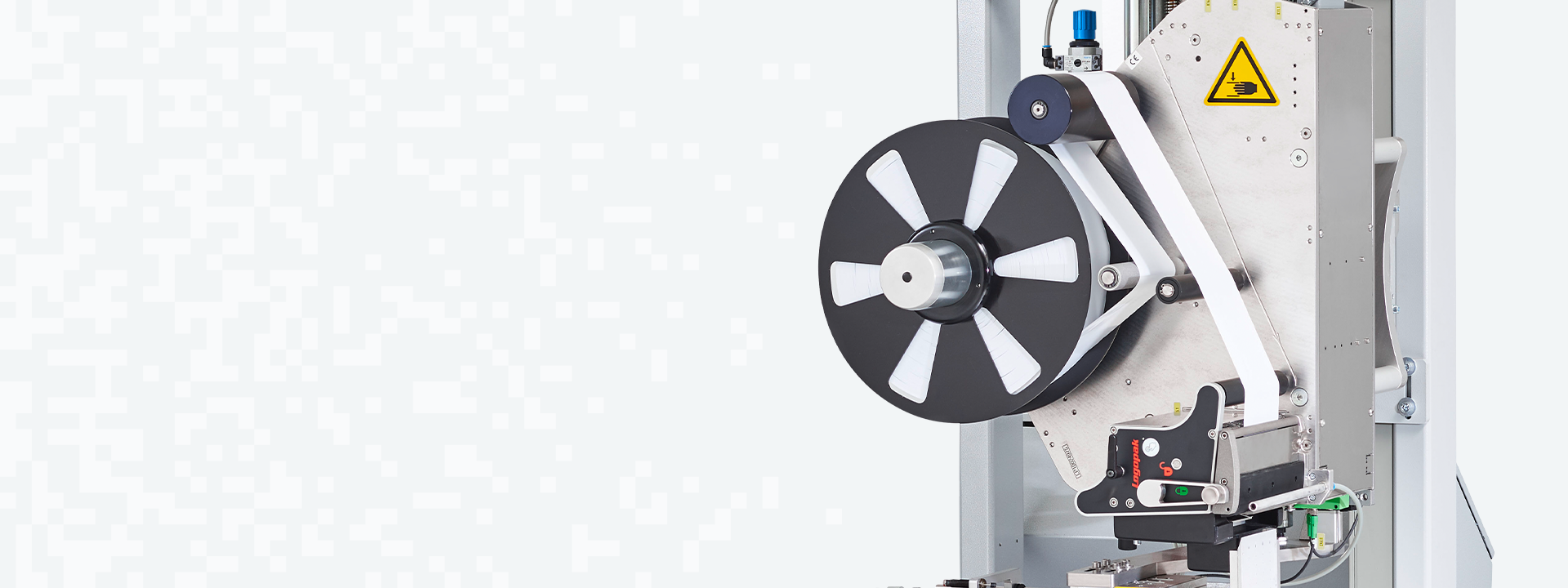

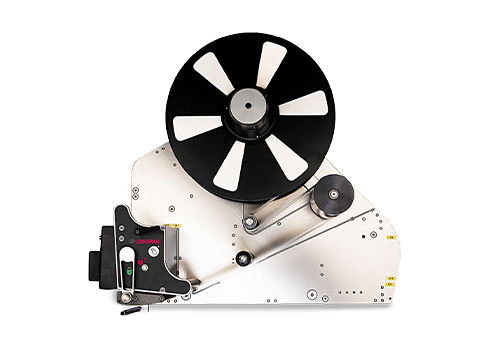

The Series 400 Linerless in detail

Robust and flexible

The high cycle rate and stable base body make the linerless product labeller a favourite for demanding industries. The wide range of applicators and different label roll widths make them flexible to use.

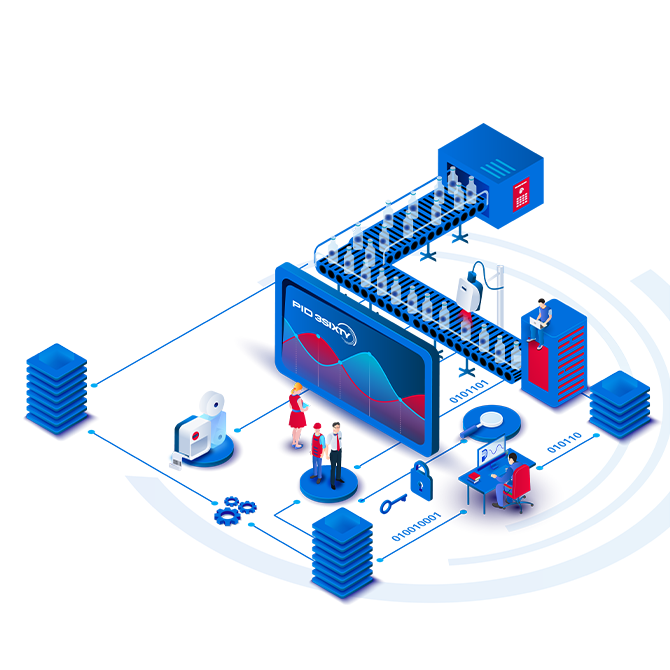

High ease of use

All processes always in view: The 10" touchscreen visualises the labels and takes care of layout management and analysis.

Low maintenance

Electronic controls are used for the digital drive technology. This makes the Series 400 Linerless particularly low-maintenance and virtually wear-free.

Thermal label material for Linerless

With the product development of TEGO® RC 730, a special silicone coating, Evonikand and Logopak offer the key to a sustainable solution using Thermal Linerless.

Your benefits of linerless labelling at a glance

- Environmentally friendly labelling with linerless labels

- More economical procurement and replenishment logistics

- Fewer stops for roll changes

- High speed

- 100% electronic control for the best results

- Direct thermal labelling for labels up to A6

- Internal database, error diagnostics and many other features

- Works as a stand-alone solution or integrated into your network

Hard Facts: The Series

400 Linerless in figures:

- Running length: 1,000 m

- Outer diameter: 350 mm

- Print resolution: 300 dpi

- Label width: up to 105 mm

- Up to 15 labels per minute

- Different applicators available

- 10" touchscreen

- Label size up to A6

- Enclosure: optional

Series 400 Linerless: Model 410

We are your partner for sustainable labelling systems

Optimise energy consumption and reduce the carbon footprint of your production with our sustainable labelling solutions – discover them now!