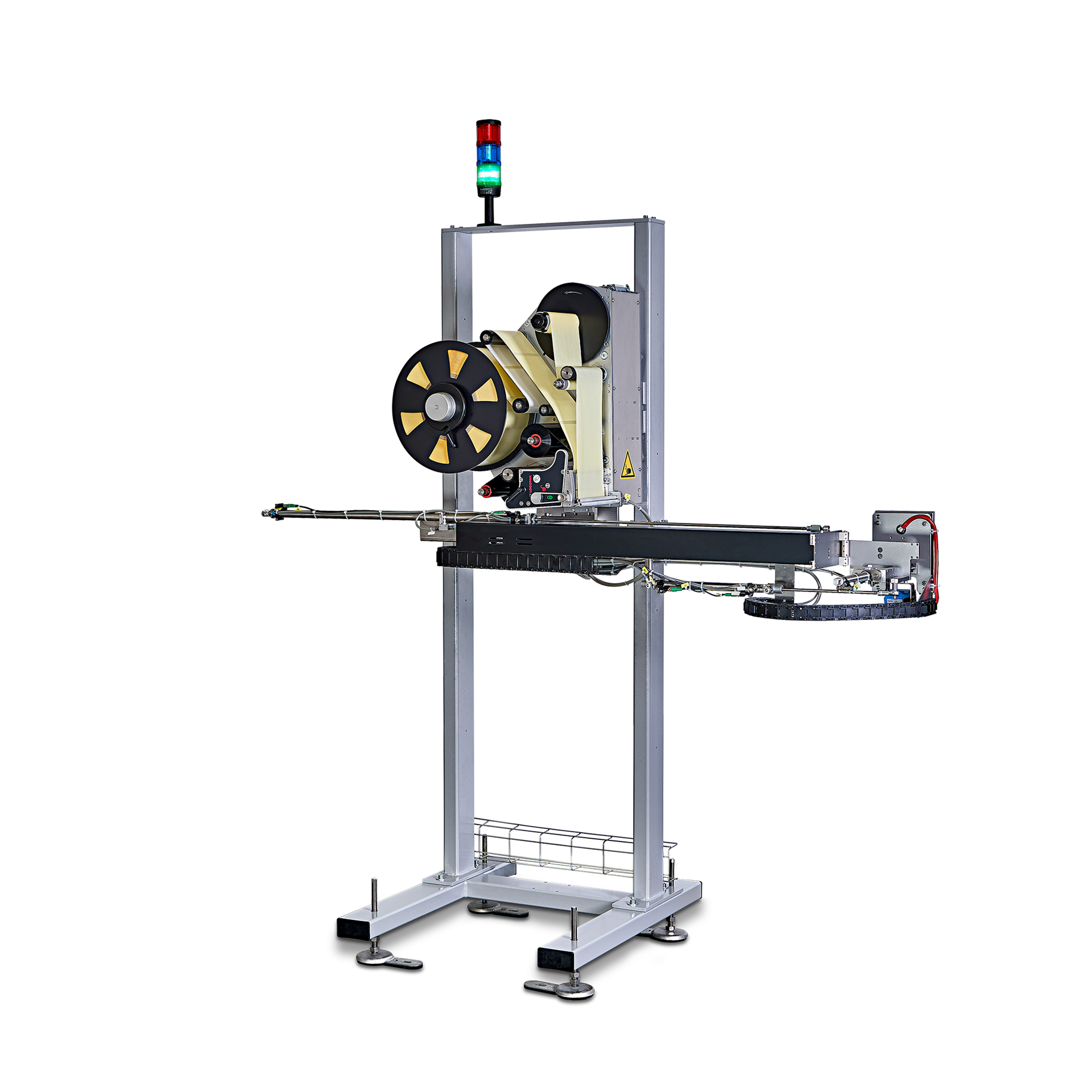

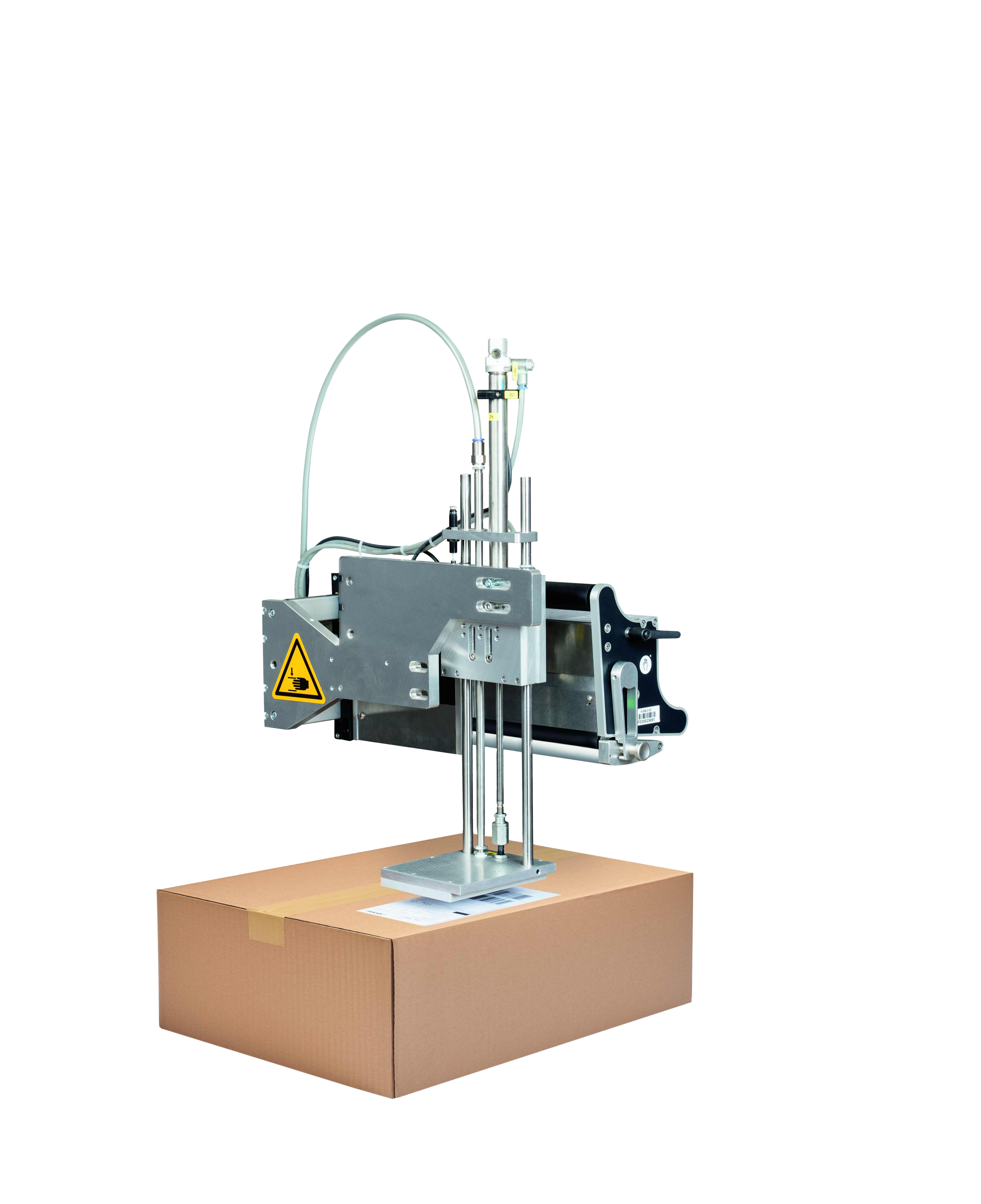

Labelling systems for every requirement

The best quality for your industrial labellingCutting-edge technology »Made in Germany«

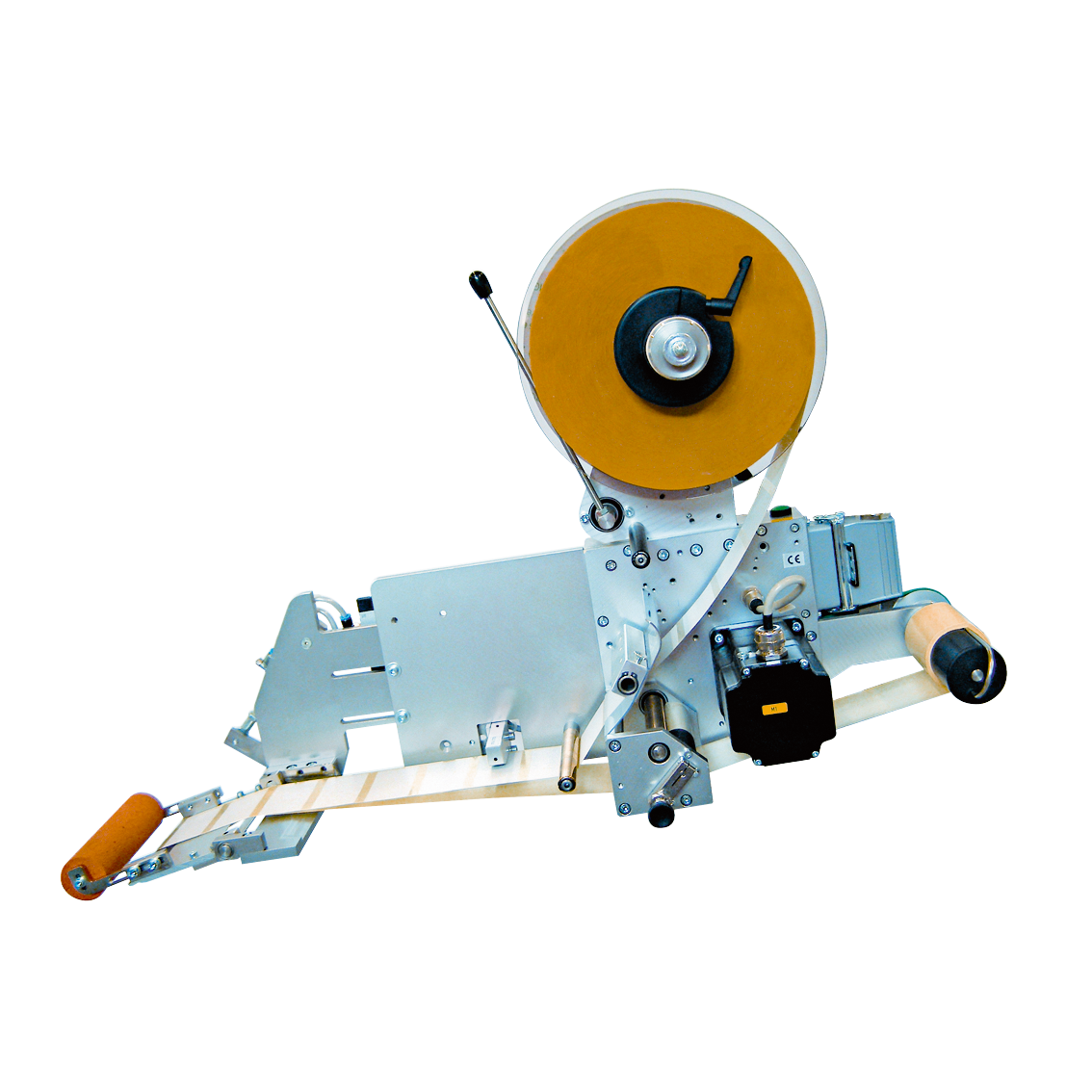

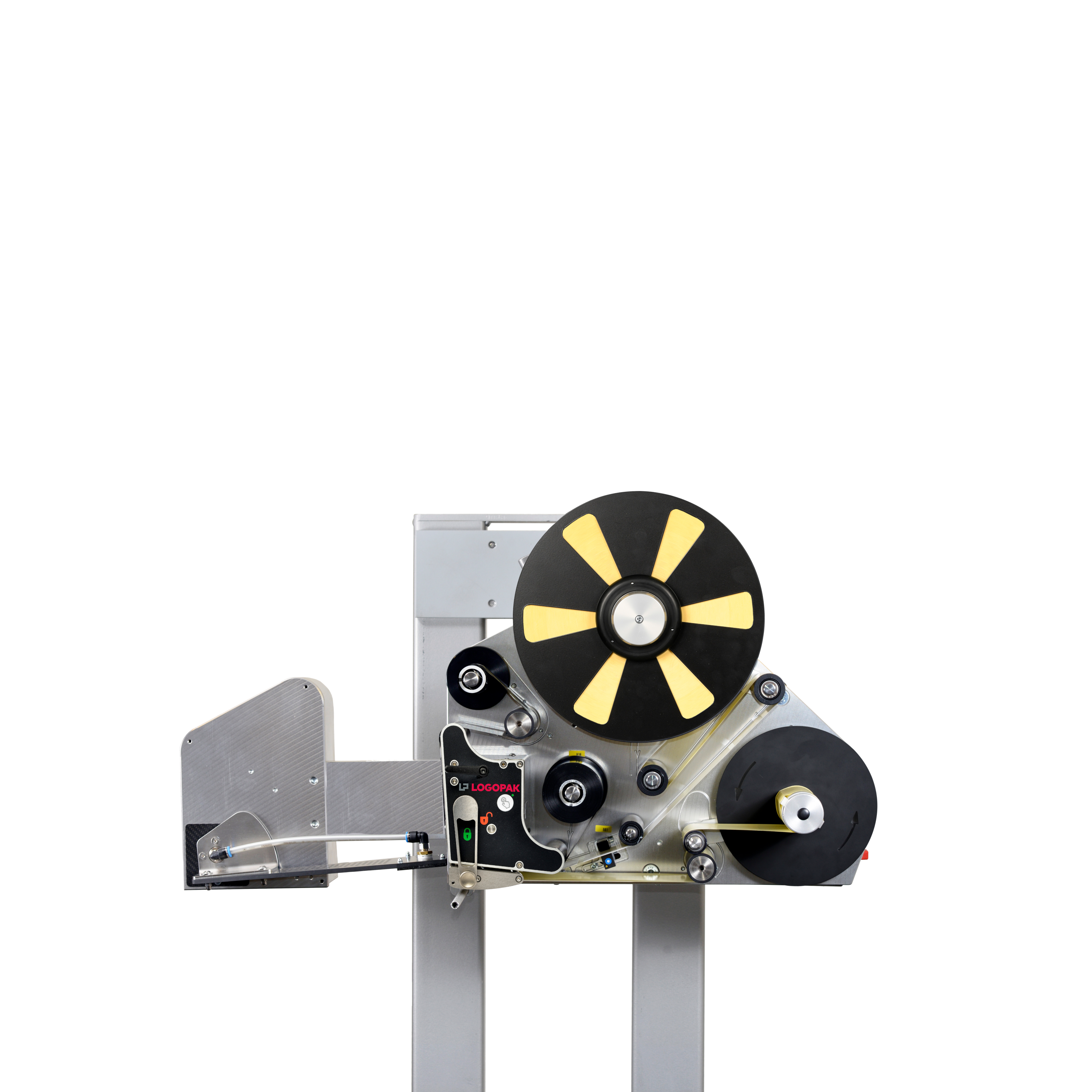

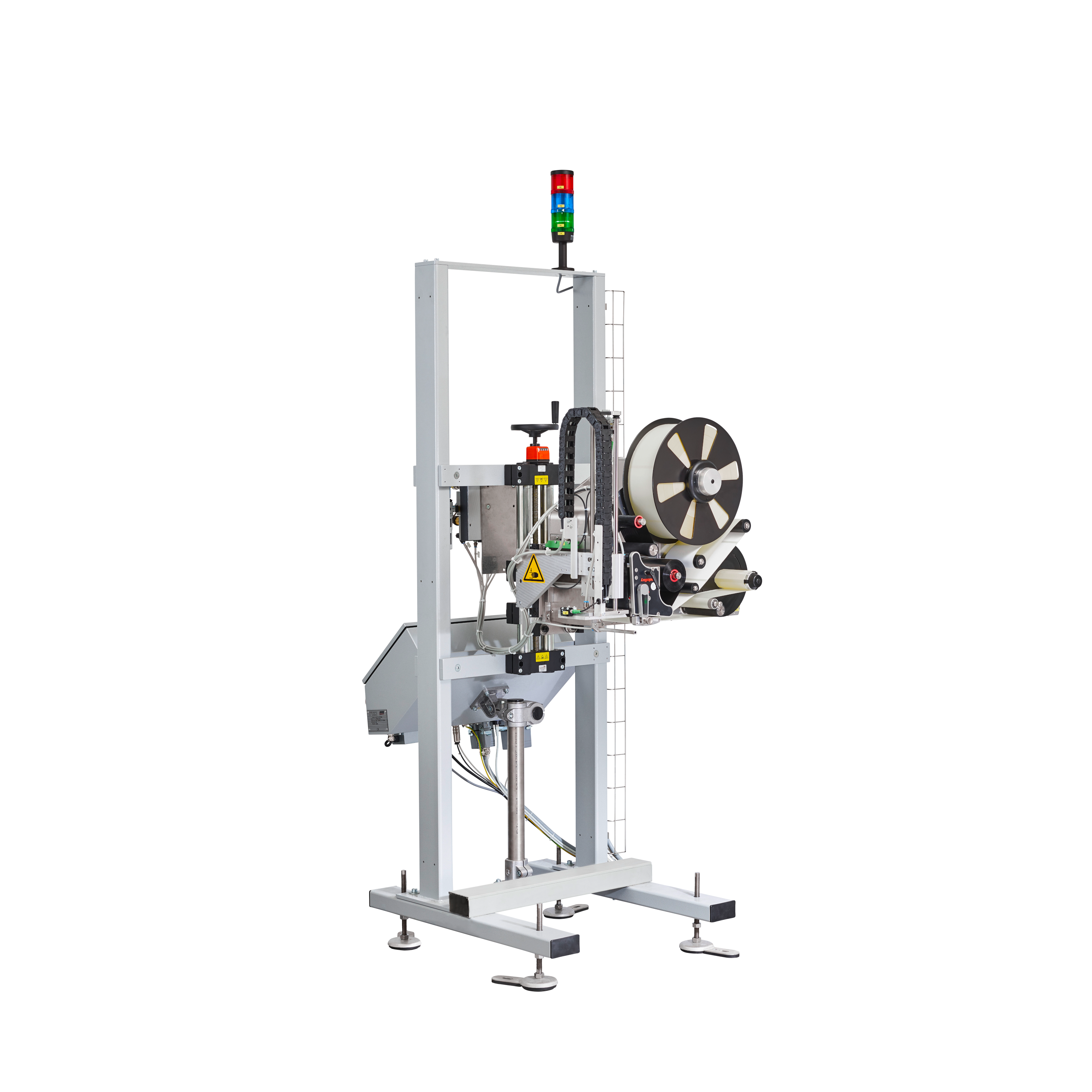

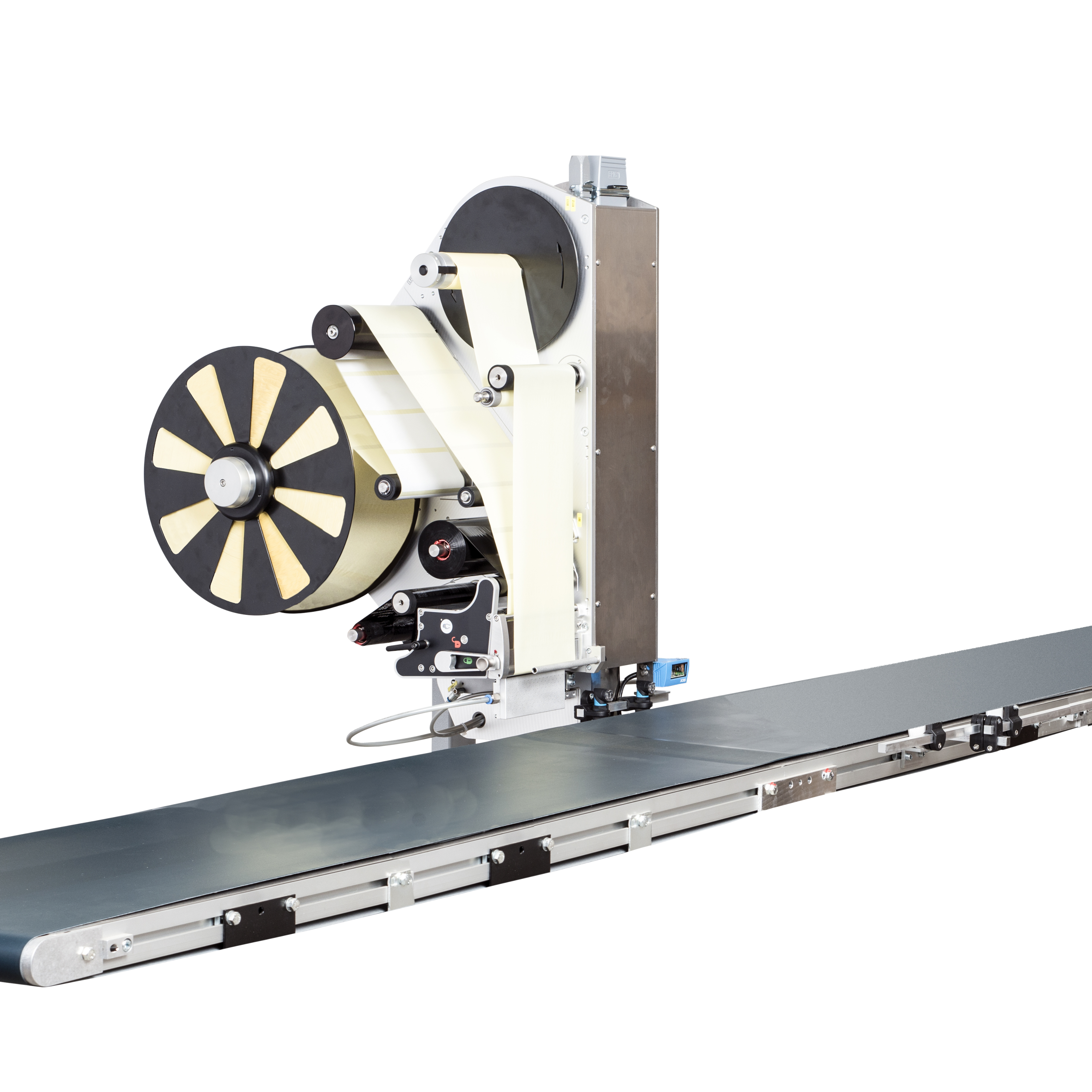

From desktop labellers as a backup solution to high-speed solutions in industrial environments: We offer eight machine series – for primary, secondary and tertiary labelling, for parcels, pallets, trays and much more. All series fulfil the highest mechanical engineering tradition »Made in Germany« and are manufactured in our factory in Hartenholm near Hamburg.

8 machine series – 55 applicators – over

2,000 possible combinations

Thanks to the wide range of applicators, our series can be perfectly customised to the needs of your company. Sensitive products, harsh industrial environments, variable dispatch packaging: Our systems fulfil all requirements, no matter how complex. We will be happy to advise you on the selection of the ideal labelling system, support you with the integration into your production lines and make individual adaptations for you. At Logopak, you get everything from a single source!

Logopak – your reliable system provider

Your benefits: This makes us the perfect partner- Maximum availability and efficiency of Logopak labelling systems

- Maximum running performance thanks to original spare parts

- Excellent delivery reliability: punctual and reliable deliveries

- Digitalisation expertise: expert in the PID 3SIXTY software

- Sustainable solutions for your supply chain

- Partnership at eye level: personalised support and advice

- Made in Germany: high-quality production in Germany

- 10-year spare parts guarantee: long-term security of supply

- Personal contact: direct and personalised customer service

- Complete solution provider: comprehensive system solutions comprising hardware, software, consumables and service