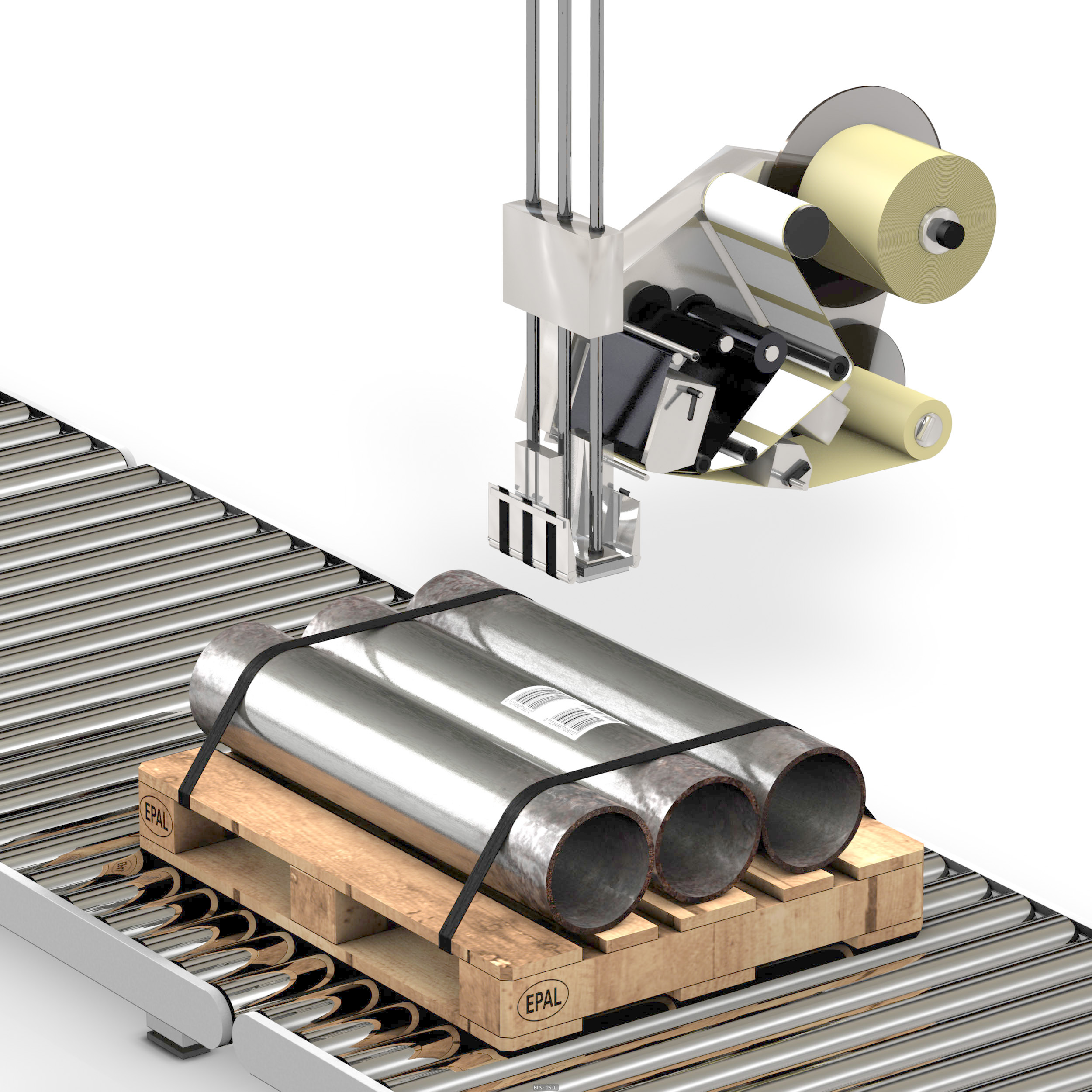

Labelling of logistics units and pallets

Tertiary packaging is usually the final transport packaging in the production chain or logistics process, and combines multiple secondary packaging in one load unit. Mostly packed on pallets or in containers, these units are ready to be transported, shipped or put into storage. Complete traceability of all units achieved through RFID technology and machine-readable barcodes takes top priority in order to ensure smooth processes.

Logopak has developed smart solutions that meet the high demands placed on tertiary labelling. Our unique Barcode Vericoder, for instance, verifies the print quality of barcodes to ensure maximum readability of the printed product information. Our innovative RFID labels guarantee complete traceability along the entire value chain. For labelling in production environments with temperatures of between -27°C and +50°C, we offer special air-conditioning and cooling solutions that provide optimal protection of your products through insulated enclosures and heating or cooling systems.

Logopak solutions make tertiary labelling even more efficient and reliable. Our innovative systems cover the entire range of pallet labelling, from stand-alone to fully integrated machines, from semi-automatic to high-performance systems designed for high-speed production lines, and from fully automated labellers that apply labels simultaneously to different faces of the pallet to all-round labelling solutions. Our in-house developed middleware LogoSoft ensures smooth integration in existing ERP systems and the customer’s IT structure, and provides reliable controlling and documentation of all labelling processes.

Practical applications

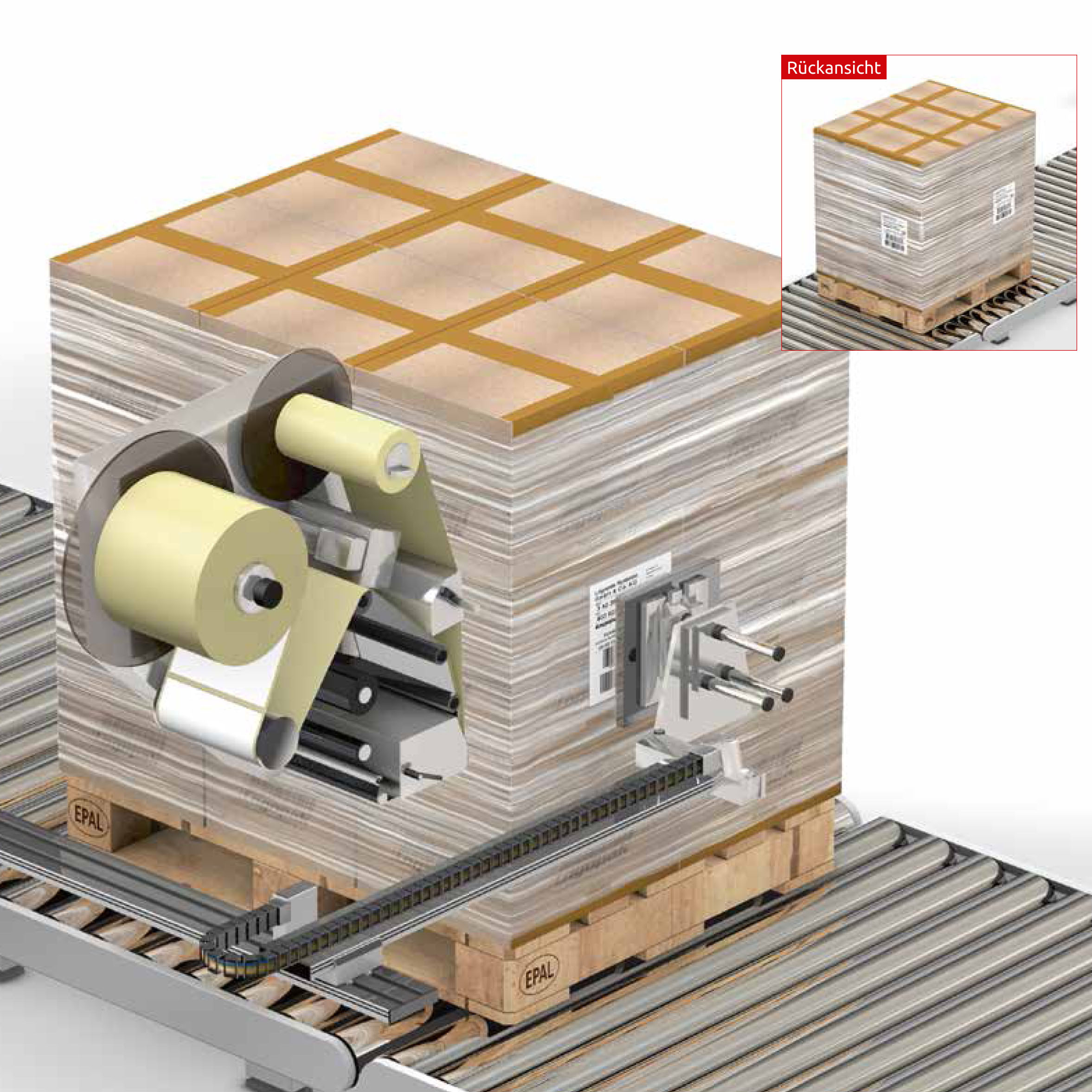

No-contact tape and banderol labelling

We have developed ideal solutions for lines with unpacked or returnable products, where the adhesive label must not be applied to the pallet. Tape labelling means that the label is applied to the pallet securing tape instead of the product itself. Banderol labelling means that the label is applied to a foil. Both methods provide labelling on 3 or 4 faces without any adhesive residues on the products.

Pallet feet labelling for internal pallet tracing

Logopak systems considerably facilitate the identification of pallets during in-house transport. Hot glue ensures that the labels are durably applied to even rough and uneven surfaces. Staples provide additional security. This method ensures reliable tracing and allocating of pallets along entire internal process chains.

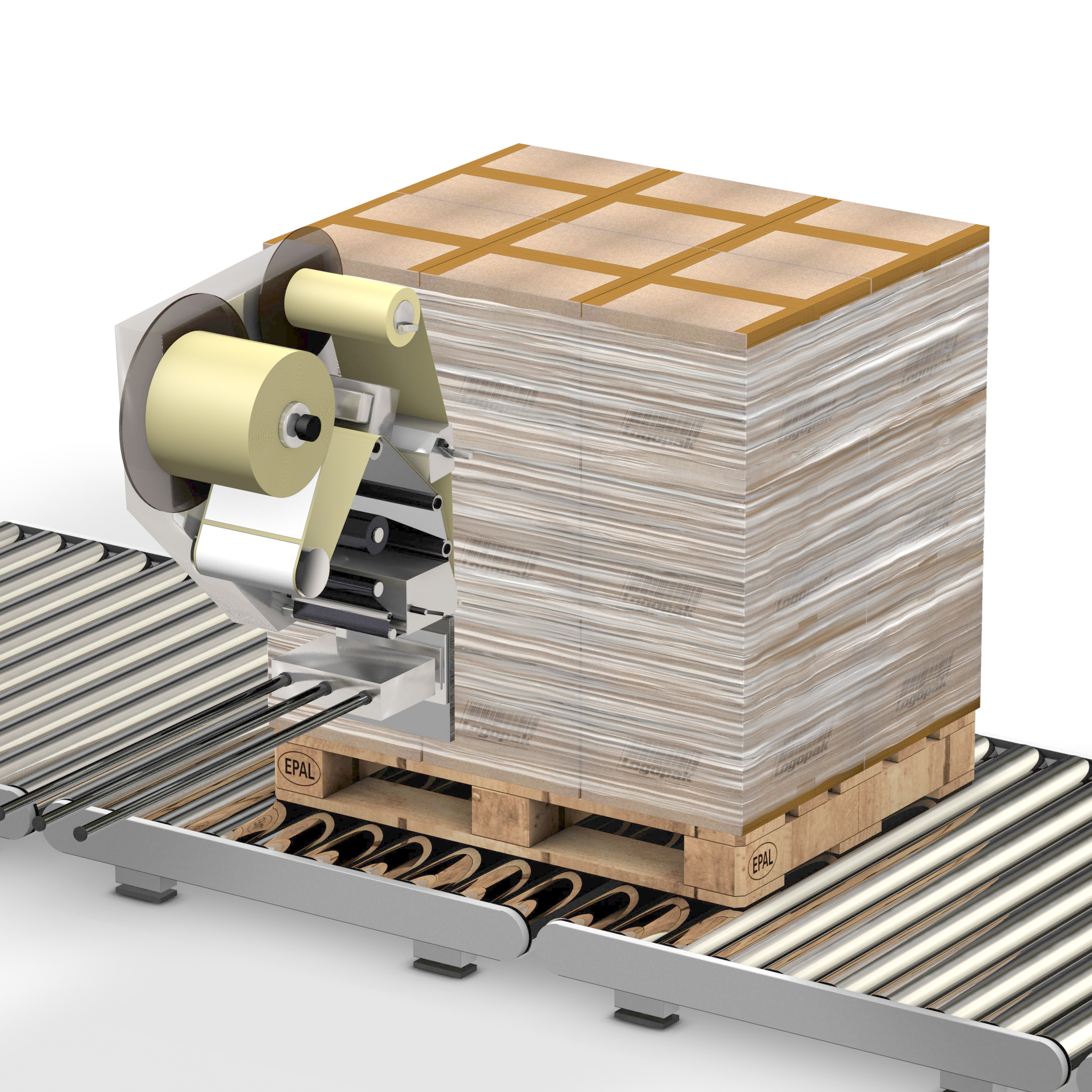

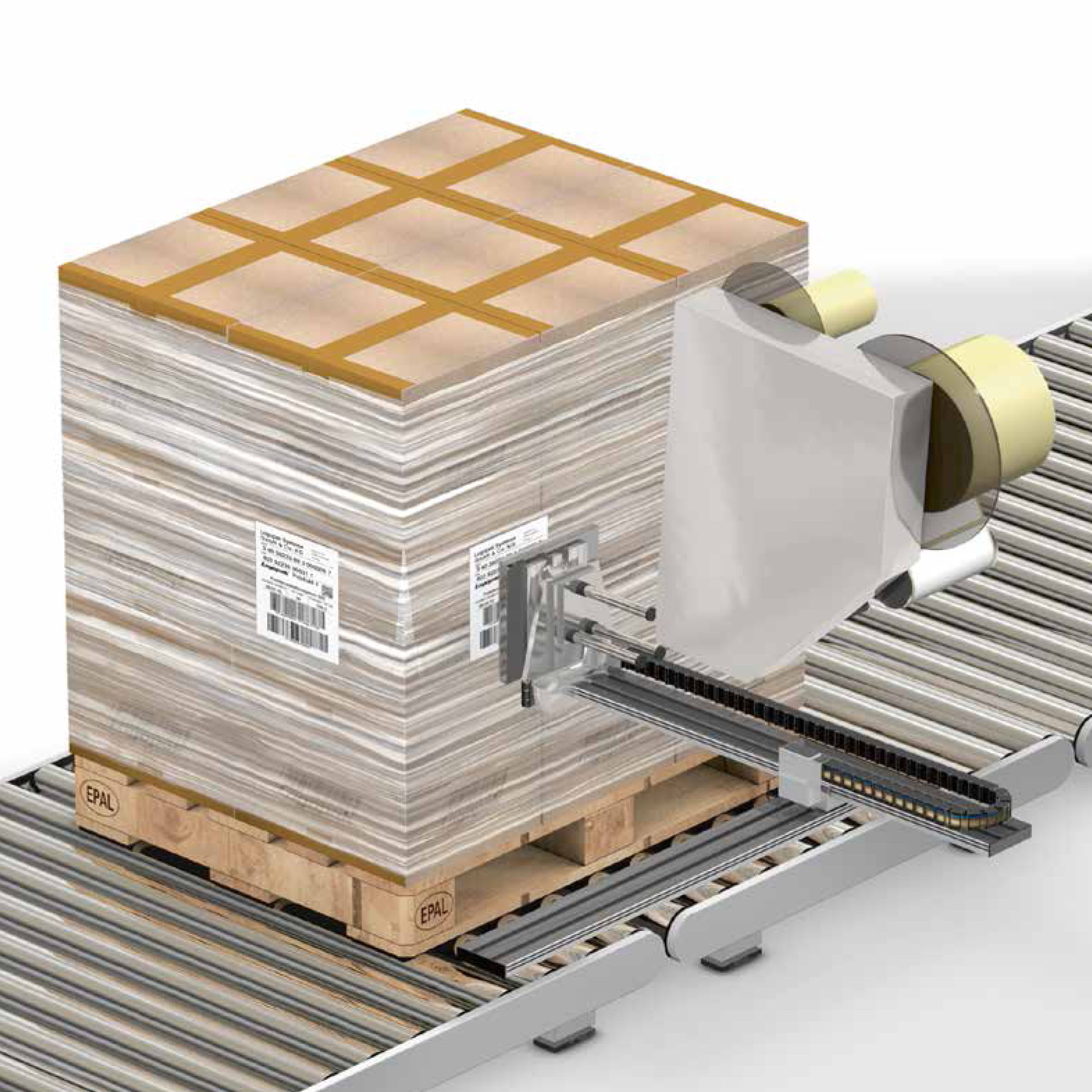

Highly efficient processes through automated 1-or-2-stop labelling

We offer automated solutions for the multilateral labelling of pallets and for production sites with limited conveyor space: 1-stop systems for labelling 2 faces or 2-stop systems for labelling 3 faces. For maximal efficient processes and high line outputs.

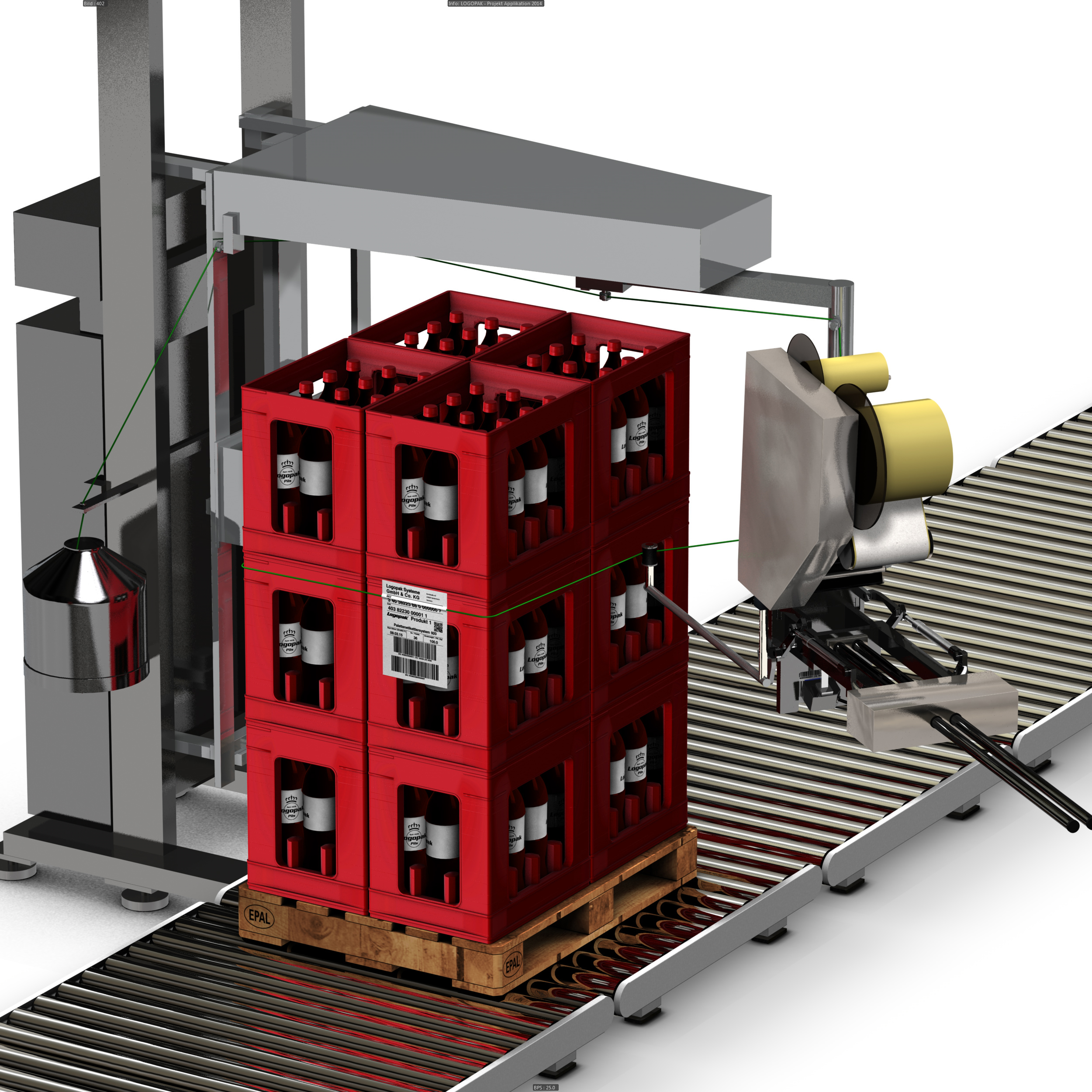

Collaborating robot solutions for complex order picking processes

Logopak’s customised and collaborating robot solutions provide flexible pallet labelling with labels applied to almost any position on the pallet, with any number of labels printed in real time. The best solution for difficult products and complex order picks.

Pallet labelling with automatic height adjustment

Individual positioning of labels through automatic height adjustment. Automated labelling of “short” pallets or double deck pallets, or to apply multiple labels one-above- the-other. The system also provides labelling according to XY coordinates: our special XY technology applies customer-specific labels to selected cartons on a packed pallet.

Matching labelling systems

Most widely used applicators

In addition to the space available in individual production facilities, the shape and size of a product are the most decisive factors when it comes to selecting a suitable applicator. Our solutions can be flexibly adapted to almost any product size and easily integrated in individual production environments.